-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

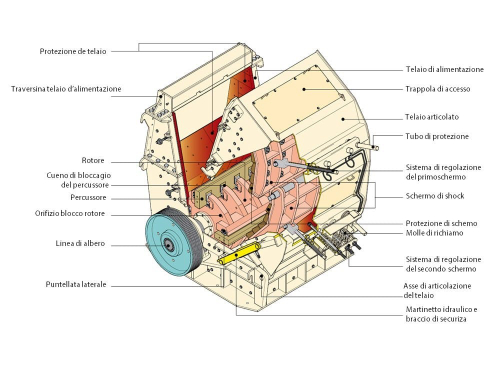

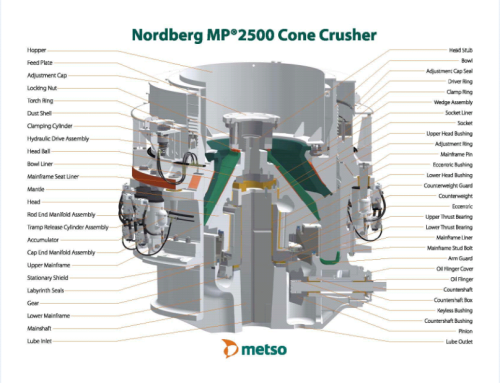

A Gyratory Crusher is a large crusher, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing,

Learn More

Gyrating crusher broken cone of the cyclic movement of the cone cavity within the shell, squeeze the material, splitting and bending, rough chopped . What Is The Working Principle of Gyratory Crusher? - Crusher FAQ. When it comes to Replacement Gyratory Crusher Parts, Excel has been crushing the market for decades.

Learn More

A gyratory crusher is an ore processing machine that crushes the ore between an eccentrically mounted cone and a crushing throat,

Learn More

15/09/2022 · WhatsApp: https://wa.me/8613621919955?text=Pls+send+us+this+message+first%2C+then+we+will+arrange+for+the+right+sales+engineer+to+serve+you%21+Your+Unique+Co

Learn More

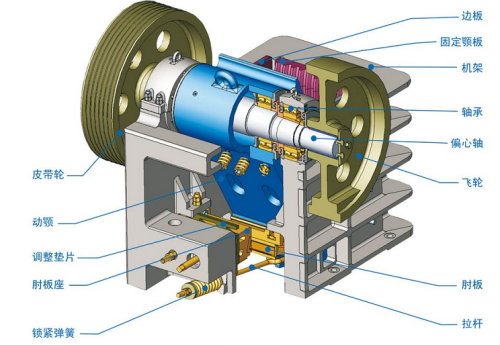

This is due to the angle that the main shaft is on. The greater angle of the cone crusher puts the pivot point below the distributor plate. The primary crusher produces a product that is gauged by the size Gyratory Crusher Cone Crusher Mantle Differences,2015-07-25 Difference between jaw crusher and gyratory crusher.

Learn More

A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides. Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening.

Learn More

17/01/ · Crushing angles may vary between the approximate limits of 22 and 30 degrees in a line of standard gyratory crushers. It is possible to use larger angles in the larger sizes of crushers because the greater weight of the individual pieces of material tends to minimize slipping. In these large machines, a difference of a few degrees in the

Learn More

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. Outotec's Superior™ MKIII primary gyratory crushers

Learn More

25/07/ · While the Secondary and the Tertiary crusher’s travels between 500-600 R.P.M. This difference in the speed results in a HAMMERING type crushing action over the SQUEEZING

Learn More

Gyratory Crushers. Gyratory crushers feature a conical head and concave surface (often lined with manganese steel) and break apart material by compression through what is known as eccentric movement. Like jaw crushers, gyratory crushers are often utilized in primary crushing stations, though they may sometimes be used as secondary crushers

Learn More

thyssenkrupp gyratory crushers in primary crushing is second to none. KB 63-75 for aggregates. Capacity: 2,600 t/h. KB 63-89 for iron ore.

Learn More

Application of gyratory crusher. The equipment investment operator is a non-ferrous metal mining enterprise focusing on mining molybdenum ore. In , using a HGT6089 gyratory

Learn More

Gyratory crushers are the most common ma- chine used in the primary crushing in the copper mining industry of Chile and worldwide, and they are

Learn More

d. It is required to feed the ore with a uniform particle size, otherwise the crusher is easy to be blocked, and the miner must be set before crushing. e. It is suitable for crushing massive ore, and sometimes the discharge particle size is too large for strip or flake ore. (A jaw crusher works in Morocco's 500tpd silver ore dressing plant)

Learn More

21/11/ · Gyratory crushers and cone crushers, while looking the same and performing similar duties, are two different machines.A quick look at a machine will allow you to determine

Learn More

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the

Learn More

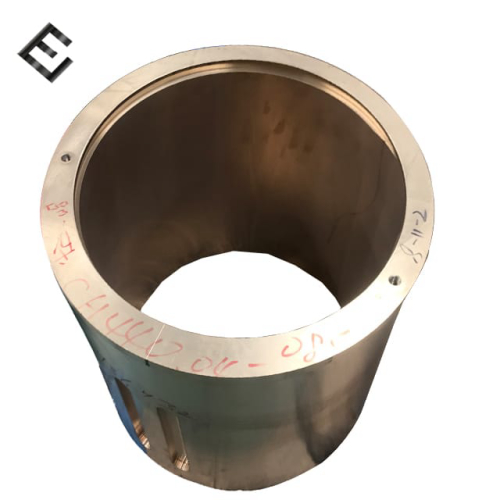

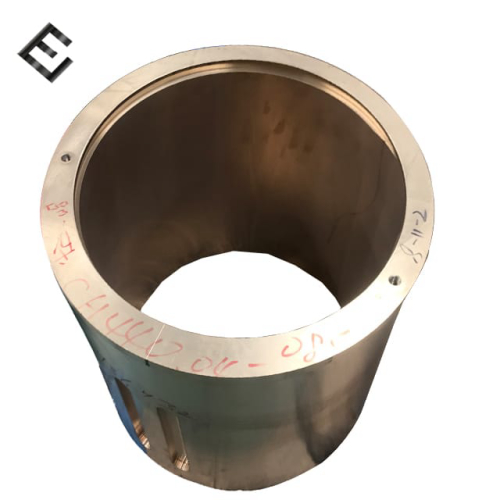

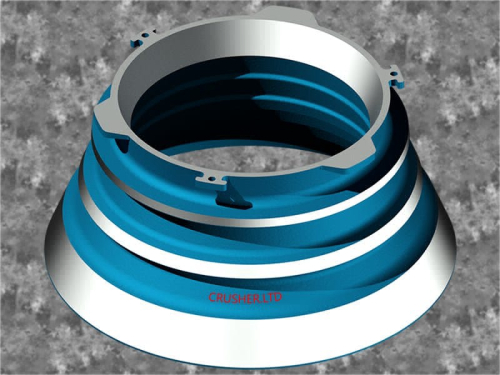

We offer Gyratory Crusher Liners tailored to your needs and manufactured for increased productivity. Here is what sets our Gyratory Crusher Liners apart: (1) Gyratory Crusher Liner design is selected based on customers' application (2) We use high quality materials and a robust Quality Control Program for all liners

Learn More

A gyratory crusher is used to crush rock between a mounted crusher cone and a fixed crushing chamber. Often used to perform a secondary,

Learn More

Primary gyratory crusher parts Improve crushing performance and prolong service life Wear parts High-quality primary gyratory crusher parts increase the crushing performance and reduce unexpected downtime. We offer standard or tailor-made parts according to your application requirements. OEM quality

Learn More

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, together with the upper part of the mantle, it forms the initial crushing zone. The coarsely crushed material is then reduced to the desired product size in the crushing chamber below.

Learn More

18/07/ · Gyratory Crusher Operation. Crusher are used to reduce the ore in size, the purpose and the responsibility of the crusher operator is to operate that crusher in such a manner as to

Learn More