-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

Energy consumption for the mills was determined by connecting a watt-hour meter in series with each mill. The meter was video-taped during operation to ensure

Learn More

In the following discussions, both roller mills and hammermills will be looked at in terms of equipment selection, operating conditions and.

Learn More

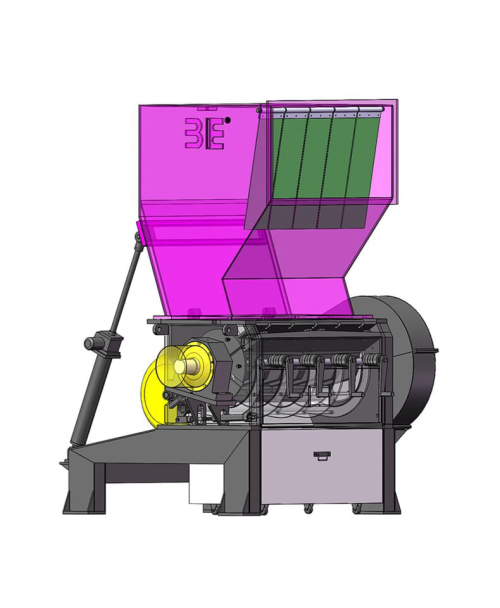

hammer mill working principle. hammer mill structure and working principle in nigeria. hammer mill structure and working principle in nigeria. Hammer mill is the most widely used grinding mill and among the oldest Hammer mills consist of a series of hammers usually four or more hinged on a central shaft and enclosed within a rigid metal case It produces size

Learn More

KEEParea around unit, drive and control station free of debris and obstacles. NEVERoperate unit without guards and all safety devices in position and functioning. ALWAYSallow unit to stop naturally. DO NOT attempt to artificially brake or slow motion of unit.

Learn More

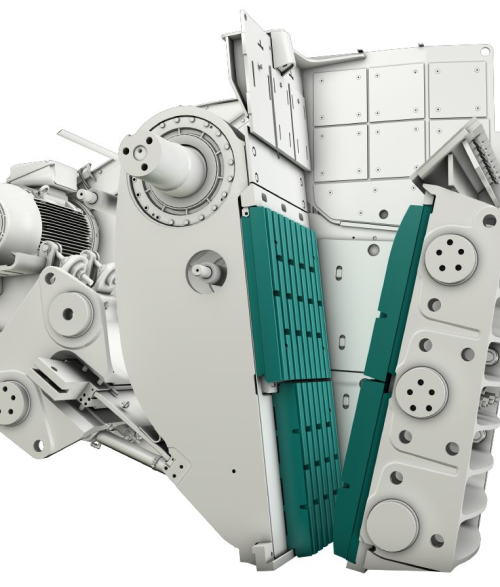

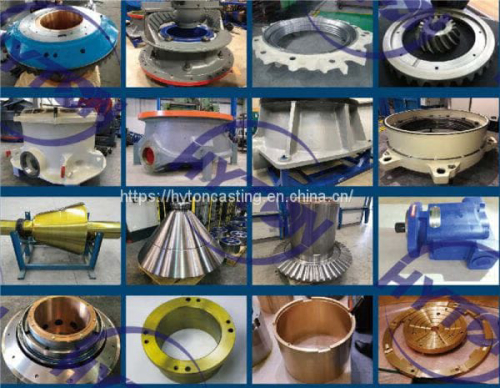

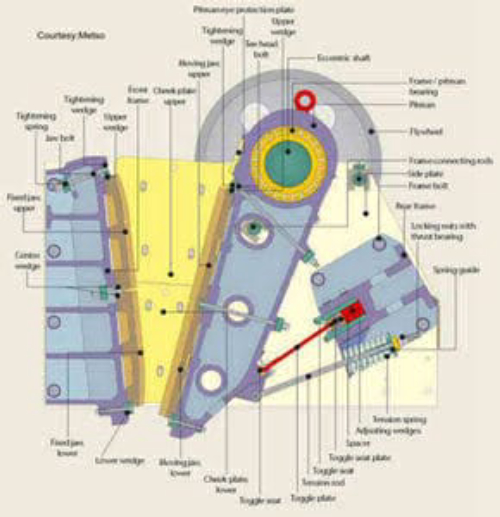

Structure and working principle: This european hammer mill is consisted by the steel frame, rotor, blow bar, grizzly screen, Hammer crusher,Hammer crusher mill,Hammering machine,Hammer Hammer crusher makes use of the high-speed impact effect of the Working Principle of Hammer Crusher.

Learn More

The conceptual design was based on the principle of design by analysis. 1.1.2 After several hours of hammer mill operation, the sieve screen holes are

Learn More

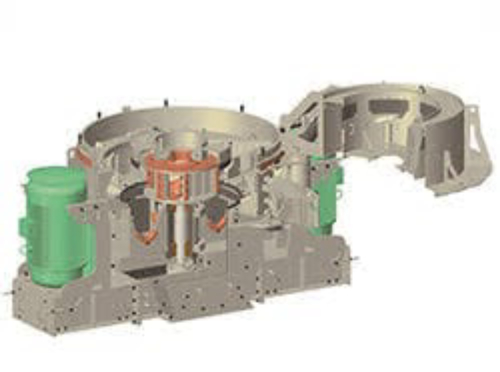

Ball mills 37 2.3.5 Stamp mills 38 2.4 Operating Principle of the Horizontal Shaft Impact Crusher 39 2.5 Design Parameters for the Horizontal Shaft Impact

Learn More

Hammer mill working principle pdf Hammer crusher (hammer mill) are applicable for various hard and fragile materials, such as limestone, coal, salt, gypsum, alum, brick and tile, etc. The crushing compressive strength of materials should not be in excess of 150Mpa. Hammer crusher is mainly used in industries such as cement, coal separation

Learn More

work carried out in improving the design, construction and testing of hammer mill by addressing some lapses associated with the design and construction of the existing ones. These in Amesbury, Massachusetts in the USA. The principle of the power hammer is similar to the wheeling machine in that they both shape the metal[4]. Incorporation of

Learn More

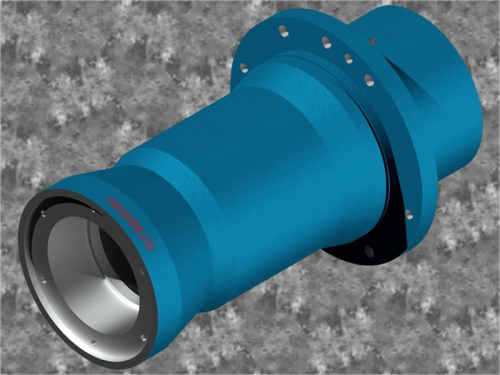

feeding (e.g., making metering into the mill difficult), grind-ing (e.g., plugging the hammer mill screen or blocking the air classifier of a jet mill), and collection (e.g., plugging the bag filters). There are two ways to grind sticky materials. The first solution is to dry the material prior to grinding, or dry and

Learn More

This type of hammer mill is well-suited for lighter materials like paper, greenwood, biomass, etc. Gravity Discharge Industrial Hammer Mills: This hammer mill makes use of swinging hammers, mounted on a shaft. The process of particle size reduction takes place by the hammering application, plus via the particle-on-particle force.

Learn More

The results revealed that, the optimum operating conditions for both A and E mills were obtained at rotor speed of. 2100rpm, cobs feed rate of 0.2 ton/h and 9mm

Learn More

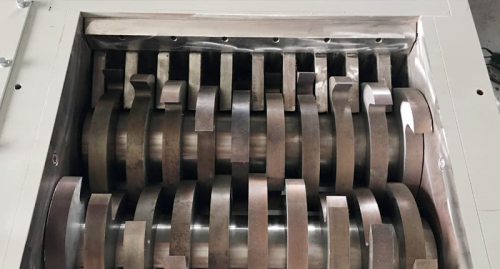

1. Hammer mills: In a hammer mill, swinging hammerheads are attached to a rotor that rotates at high speed inside a hardened casing. The hammer mill consists of a steel casing in which a central shaft is enclosed to which a number of swinging hammers are attached. When the shaft is rotated the hammers swing out to a radial position.

Learn More

The hammer mill operates on the principle of impact between rapidly moving hammers mounted on a rotor and powder.

Learn More

This machine operates on the principle of reducing the material by striking it while in suspension, as opposed to attrition. The material is fed

Learn More

PDF | Our paper presents the hammer mill working process optimization problem destined for milling energetic biomass (MiscanthusGiganteus

Learn More

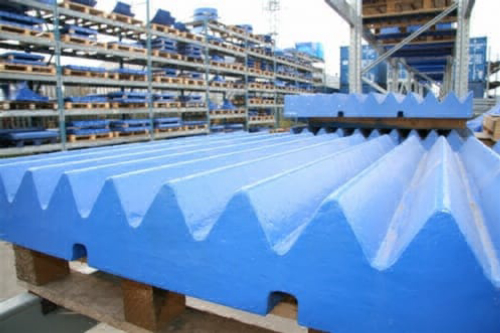

The hammer mills work according to the principle of crushing by multiple impacts. □ By means of the direct blow of the hammer mill beater on the.

Learn More

Mar 23, 0183 32 Pin mill work by similar principle as hammer mills impacts and shearing but with typically faster tip speed rotor-stator configuration of intermeshing pins which impact the particles as solids are directed through the inter mesh pins The mill product leaves by centrifugal forces to the periphery and is then collected or further processed

Learn More

The working principle of the hammer mill is simple to understand. The principle is illustrated in Fig. 1 (a). It only requires choosing an appropriate motor, crushing hammers/knives and material to be crushed. It operates on the principle of impact between rapidly moving hammers mounted on the rotor and the stationary powder bed.

Learn More

Working principle of hammer mill machine pdf. 2.5 Operating Principles Figure 2-1 illustrates the basic operating principle of the Prater Full Screen Hammer Mill. The G Series mill uses a shaped grinding chamber with distinct grind and release zones. Coarse material is fed to the mill through the top product inlet usually by a gravity rotary feeder

Learn More

feed processors decide which mill (roller or hammer) is best suited for their grinding needs. operating parameters of roller mills and hammermills,.

Learn More