-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

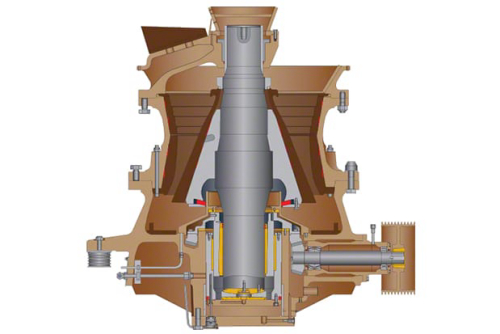

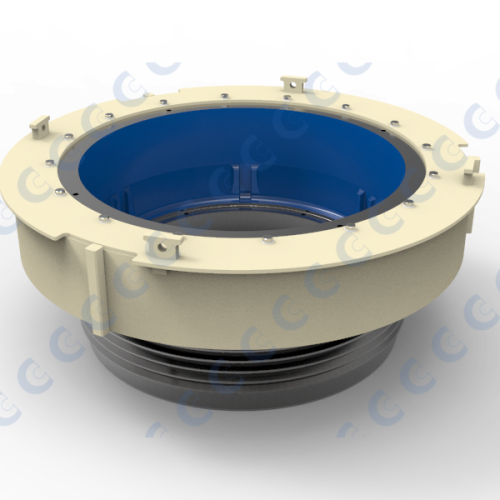

gyratory crusher maintenance manual | Mobile Crusher Philippines. Gyratory Crusher is used in quarry as quarry crushing equipment. Gyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center

Learn More

A gyratory crusher is a significant investment for any mine. Poor maintenance can result in unplanned shutdowns for repairs, premature failures and

Learn More

the functions of a gyratory crusher. The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions It is designed so that you can easily access and remove the eccentric assembly bushings and hydraulic piston.

Learn More

17/2/ · In the Gyratory crusher, the original discharge setting may be maintained for the life of a single set of alloy crushing surfaces with only one resetting of concaves. Raising the

Learn More

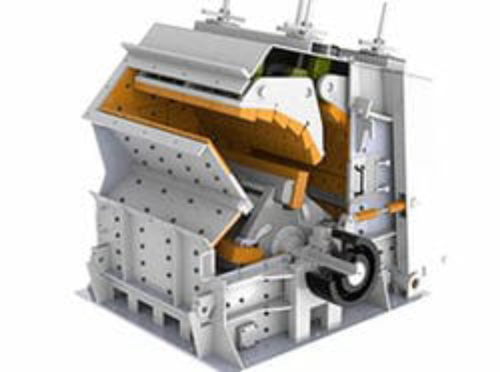

Close examination and good maintenance of your crusher protects your plant's overall productivity. By acting fast, you can avoid poor performance, stoppages and costly repairs. Our regular crusher inspections and ongoing technical support ensure your equipment keeps operating at maximum efficiency.. In addition to these comprehensive inspections, our crusher maintenance services include

Learn More

But for hard rock mining, the use of gyratory crushers, cone crushers, and/or jaw The maintenance strategy for a gyratory crusher will be largely

Learn More

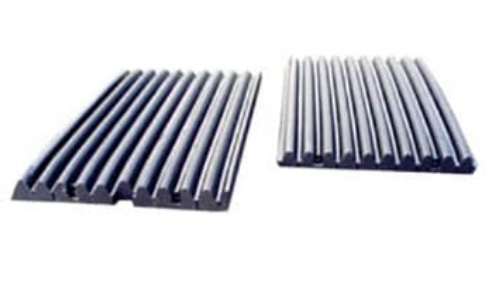

A gyratory crusher includes a solid cone set on a revolving shaft and Maintenance of the wear components in both gyratory and cone crushers is one of

Learn More

The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions. It is designed so that you can easily access and remove the eccentric assembly, bushings and hydraulic piston through the top of the crusher, hence the name

Learn More

GYRATORY CRUSHER TYPE TS TSU 7500762 M 8 Rev 0 Item Task Repairs Required Date from CP 261 at Chile Technological University of Professional Institute of Technical Training Center, Valparaiso

Learn More

21/4/ · #viral #viralvideos # ironore #kobelcogyratoryconecrusher #kobelcocrusher #ironoremining #ironorecrushing #ironoreprocessing #maintenance #shutdownma

Learn More

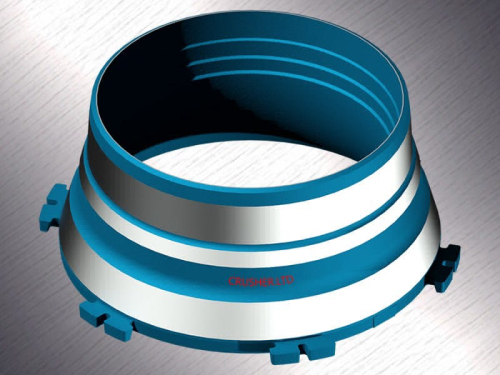

9/1/2022 · HOPPER CLEANING OF GYRATORY CONE CRUSHER FOR SCHEDULED MAINTENANCE OF RING SEALINGPlease

Learn More

High-power crushing and easy maintenance with the Gyratory Crusher NT Get the best features of the previous model with added safety and usability functions.

Learn More

the perfect blend of experience and innovation the superior gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: easy maintenance and service designed for low service requirements and ease of operation, the superior primary gyratory will readily fit

Learn More

Jones advises: “Always ensure the wear parts are fastened into the machine properly. With jaw crushers, if you allow the jaw dies to move during

Learn More

The design of the gyratory crushers and jaw gyratory crushers is based on more than one hundred years of experience. thyssenkrupp gyratory crushers represent today's state-of-the-art. They are designed for high throughput rates and high crushing ratios at low operating and maintenance costs. Maintenance friendly design

Learn More

Implementing a preventive maintenance program is the best method of keeping a crusher in good operating condition for a long period. Preventive

Learn More

PDF | A cone crusher is used for crushing rock. The vast majority of these installations are found in mineral processing plants.

Learn More

The unique top-service design prioritises safety, easy maintenance and efficient crushing performance. Unlike other gyratory crushers, which

Learn More

why choose our Gyratory crusher: Efficient and Intelligent Production. High Output Yet, Low Crushing Costs. Simpler Operation and Maintenance. Sufficient Supply of Spare Parts, Worry-Free Operation. Strong Adaptability, Applicable for Severe Crushing Conditions. Able to Work Continuously under High Intensity, It has longer service life.

Learn More

Gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches). The feed material should be at

Learn More

Primary Crushing Mineral Processing & Metallurgy. The term "primary crusher," by definition,might embrace any type and size of crushing machine.The term implies that at least two

Learn More