-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

Features of the Gyratory Crusher High capacity per dollar of investment, Annular discharge opening minimizes slab ; makes for more cubical product. Shape of receiving openings favourable for slabby material. This, plus point 2, gives the machine a distinct advantage over the jaw for handling thinly stratified stone.

Learn More

Crusher automation. Outotec IC70C™ is a crusher automation system that further improves the operation of your ® HP™ crusher. Using it can increase your production by more than 10%. With Outotec IC70C™ you can control maintenance, setting modifications, production follow-up and data extraction.

Learn More

More than 100 customers, distributors and members of the press joined Construction Mobiles recently as the new S type gyratory cone crusher range

Learn More

IS 4255 (1967): Gyratory and Cone Crushers [MED 17: Chemical Engineering Plants and A gyratory and a cone crusher are similar in construction except.

Learn More

Jaw Crusher VS Gyratory Crusher Performance Different 1. The rotating speed of the movable cone of the gyratory crusher is low, the stroke is small. And the ore is mainly crushed and broken and bent. The cone crusher has 2.5 times higher rotating speed and 4 times larger swinging angle than the gyratory crusher, so the ore is impacted quickly.

Learn More

1000 TPH Primary Gyratory Crushing Plant Item #1 - Fuller-Traylor Model 42-70 Type TCB Gyratory Crusher with cast steel two piece mainframe, 400 - 4,000 volt electric motor, direct shaft drive, hydraulic $145,000. ALLIS CHALMERS Cone Crusher for sale amp rental Rock amp Dirt Search from 1000 39s of listings for new amp used ALLIS CHALMERS

Learn More

Type: Cone / Gyratory Crushers; Scale: Production Applications: Ore and mineral processing; Waste processing or recycling Feed: Dry solids ® LT220D™ Mobile Crushing And Screening Plant from Metso. Features. ® LT220D ™ is a new innovative way to combine crusher and screen onto the same chassis. LT220D can be equipped

Learn More

Gyratory Crusher shape of two cones are steep, and can be fixed upright truncated cone is the cone, fixed cone is inverted truncated cone, which is mainly to increase - Fuller-Traylor gyratory crushers

Learn More

Optimised crusher tooling solutions for greater efficiency and safety, Overview, What we offer, Key benefits, Product features, Share, Contact, Products, Raptor® Cone Crushers for Mining, Gyratory Crusher Wear Plates, Gyratory Crusher TS, Gyratory Crusher NT, Cone Crusher Liners, EXCEL™ spare parts and liners for ® MP™ cone crushers,

Learn More

Gyratory And Cone Crusher. 3.1.2.3 Fine bowl gyratory crusher- A gyratory crusher in which the discharge setting can be adjusted to less than 20 mm. 3.2 Cone Crusher - The cone crushers are generally classified, depending upon the type of the cone and the throw, as standard cone and short-head cone crushers

Learn More

10/12/ · It crushes rocks by rotating the vertical shaft and crushing the rocks in a circular motion where they fall out the narrow bottom when they are small enough.A gyratory crusher is used both for primary or secondary crushing. Cone Crusher,

Learn More

A Cone Crusher will deliver a 4:1 to 6:1 reduction ratio. As we set the closed side setting tighter to create a finer output, we also reduce the volume or throughput capacity of the machine. Generally speaking, multiplying the closed side setting by two is a good guide to the top size of the gradation exiting the machine. A general rule of thumb for applying Cone Crushers is the

Learn More

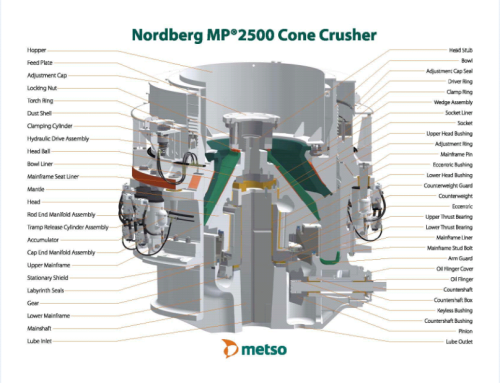

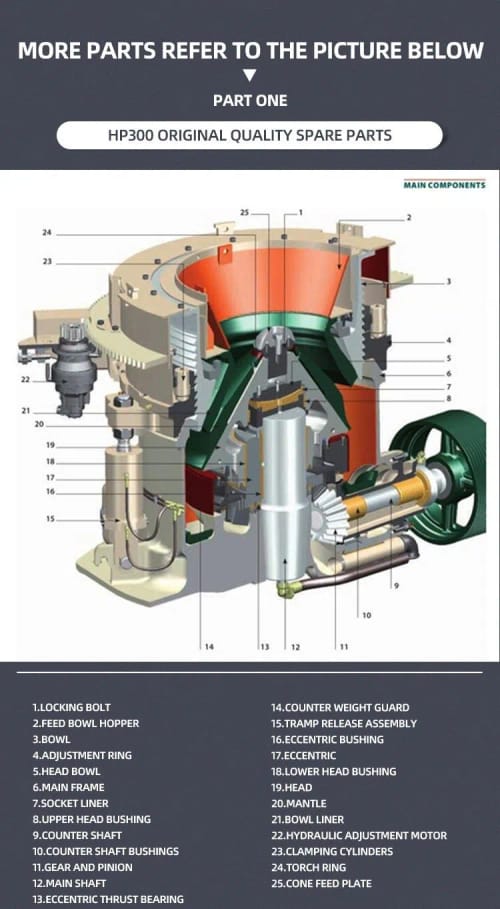

When gyratory cone crusher works, electromotor through horizontal axis and two bevel gear drives eccentric bushing rotation, when eccentric bushing turns, the work principle of gyratory crusher. the work principle of gyratory crusher. As a professional crushing and grinding equipments manufacturer, Gyratory and cone crushers work How Does A Gyratory

Learn More

The angle of nip in gyratory crushers has definite limitations. In the older straight element crushing chamber, the angle ranges from 20" to 24". On large primary crushers, using curved or nonchoking concaves and where gravity is of marked aid to nip with the large pieces at the mouth. the angle runs from 25" to 30°.

Learn More

South Africa Cone Crusher Market, By Type ( , Hydraulics, and Gyratory), By End-User Industry (Mining, Construction and Recycling), By Mobility (Stationary, Portable-Wheeled, and Portable-Tracked Mounted), By Sales Type (New Equipment Sales and Aftermarket Sales), By Power Source (Electric Connection, Diesel Connection, Dual Connection), By Region, Competition Forecast & Opportunities, 2027

Learn More

G10SEC TRMNL PLUG BUZ12-S 1756-a10 dimensions parts of stone crusher spare bush for a cone crusher mobile crusher parts. High-Speed Gyratory Crushing --> Fine Cone Crushers. Malaysia crusher machine,Gyratory cone crushers,Jaw crushers Gyratory crusher type KB 137-190 (54″-75″ installed in a semi-mobile crushing plant working in a copper ore

Learn More

Gyratory Crusher Wear Parts For Popular Brands From New. The primary gyratory crusher wear parts have the most important role in rock size reduction in mine operations as the crushing process starts from a Crusher Parts, Concave, Mantle manufacturer / supplier in China, offering Superior Primary Gyratory Crusher Sg5474 Pinionshaft Arm Liner Lh

Learn More

This G series Gyratory Crusher has a large feed opening and a grooved mantle, making them suitable for crushing large boulders. G-Type cone crushers are

Learn More

Unique Gyratory Hydraulic Cone Crusher For Sale ; Application: secondary&fine crushing, Granite, Basalt, Quartz, Fldspar etc. ; Motor Type: AC Motor ; Capacity(t/h):.

Learn More

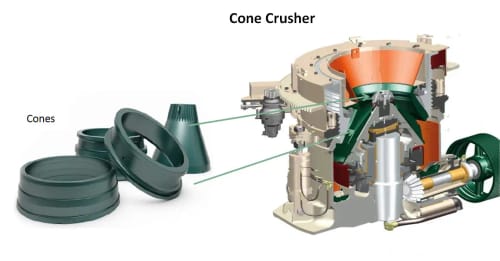

Gyratory crushers and cone crushers, while looking the same and performing similar duties, are two different machines.

Learn More

Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages. Sometimes, however, the grain size of the processed material is small enough by nature and the traditional primary crushing stage is not needed.

Learn More