-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

The invention relates to a reciprocating grate cooler in which the drive arrangement is enclosed by a drive housing, the interior of which is closed off so as to be airtight against the atmosphere, but by contrast has a pressure equalization connection to the interior of the cooler housing. Such a reciprocating grate cooler is distinguished by a substantially reduced expenditure for the

Learn More

Grate Cooler adalah sebuah alat pendingin, dimana alat ini berfungsi untuk mendinginkan clinker keluaran dari kiln. Alat ini berkerja dengan cara meniupkan angin dari bawah plate.Untuk mendinginkan

Learn More

ETA Cooler Grate Cooler Cooler Efficiency @ 0,85 Nm³/kg recuperation air 77,8 % 73,9 % Wear Grate plates 100 % in clinkerProtection Autogenous protection Due to pebble layer Heat Protection Safe due to higher clinker bed and pebble lane filling Direct contact between hot clinker and grate plate Stroke Length

Learn More

reasons explain why clinker cooling is an important phase in Zndex Terms-Clinker, Coanda nozzle, grate cooler, KIDS, red river, snowman. Clinker.

Learn More

Grate cooler. Production Capacity: 600~10000 t/d. Heat recovery rate: ≥72%. Application: cement, silicate products, new building materials, etc. . The grate cooler is a

Learn More

PDF | The reasonable control of the grate cooler is the key factor to ensure the heat exchange and cement clinker quality during the clinker cooling | Find, read and cite all the research you

Learn More

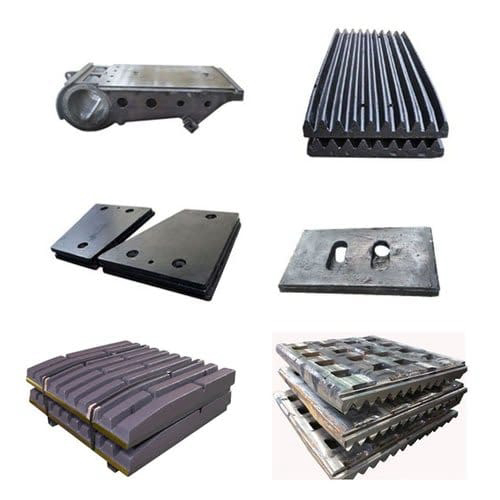

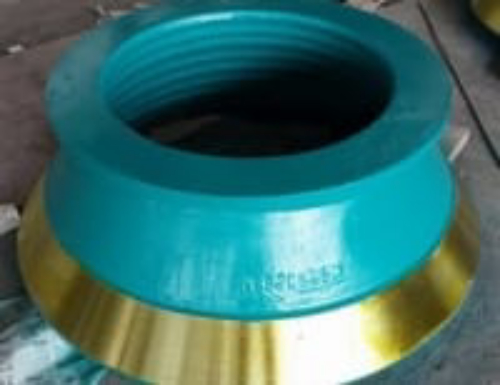

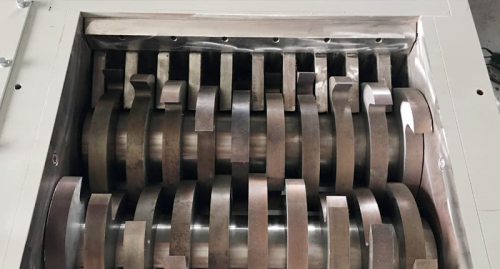

The grate cooler is composed of upper case, lower case, grate bed, grate bed transmission, supporting device for grate bed, clinker crusher, funnel, drag chain conveyor, automatic lubricator, cooling air unit, and etc.

Learn More

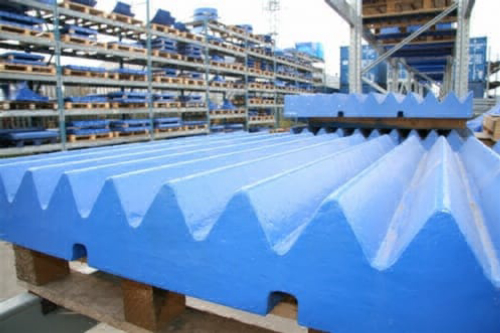

The grate of this grate cooler comprises a plurality of stationary and movable grate plate carrier beams on which a plurality of grate plates provided with cooling air bores are secured. The

Learn More

The grate cooler heat radiation was measured using infrared thermometer (561-566 nanometer wavelength). This compared the surface temperature to the surface area and values obtained were tabulated on Table 3.3. 3.2 Calculation Basis for Mass and Heat Balances. Basis for material: one (1) kg and 0℃ of clinker is usually taken as the basis. 3.2.1 Cooler Mass and

Learn More

The cooler efficiency was found to be. (75.53%) at this stage of the clinker production process. This study revealed that the grate cooler

Learn More

Grate cooler thermal Analysis.ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Scribd is the world's largest social reading and publishing site.

Learn More

cooler grates MAGOTTEAUXhas developed new alloys and designs that offer great benefits to conventional coolers, by enhancing both product performance and lifetime. Wear and thus performance of the cooler grate plates depend to a large extent on their location in the cooler.

Learn More

The invention relates to a grate cooler, in which the drive device is surrounded by a drive housing, the inner space of which is sealed in an airtight manner in relation to the atmosphere, but on the other hand has a pressure-equalisation connection to the inner space of the cooler housing. Such a grate cooler is characterised by considerably reduced expenditure for sealing

Learn More

The grate cooler is the main equipment for clinker cooling and heat recovery in the sintering process of cement clinker, and maintaining the grate cooler.

Learn More

Extensively, the grate coolers are used in cement industry in order to recover heat This work focuses on the thermal performance of the clinker cooling.

Learn More

01/13/22 12. fFixed Inlet Grate. Objective of Fixed inlet grate is to create a. homogeneous clinker bed of uniform. resistance against the passage of air. 5 to 6 Rows of Fixed grates (3 meter) are

Learn More

ETA (η) Cooler totally encapsulates the evolution of clinker cooling in one complete system. Claudius Peters began by marketing the grate cooler in.

Learn More

The grate cooler is the main equipment in calcining system of the cement plant. Its main function is to cool and transport the cement clinker. It also provides hot air for rotary kiln and decomposing furnace, and it is the main equipment for heat recovery in calcining system. Grate cooler of CHAENG is new energy-saving clinker cooling equipment

Learn More

Figure 1: Cross- sectional view of clinker cooling process inside a grate cooler. Figure 2: Overview of the conceptualized clinker cooler and clinker furnace.

Learn More

Clinker coolers must take clinker from ca. 1400°C to ca. 100°C, with maximum possible heat going back to the kiln. Because kiln rotation separates fine and coarse grains across the kiln and because each require different air pressures for cooling, traditional grate coolers produce ‘red rivers’ of hot, fluidised clinker that flow to the

Learn More

A grate cooler can be regarded as a simple heat exchanger through which the clinker passes across or counter to the cooling air flow and a direct heat transfer takes place between the hot clinker and the cold cooling air. The desired maximum recuperation of the heat from the clinker cooler for use in the kiln system for specific quantities of secondary and tertiary air demands

Learn More