-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

Jaw crusher: The material is crushed between a fixed jaw and a mobile jaw. The feed is subjected to repeated pressure as it passes downwards and is

Learn More

Jaw Crusher - an overview ScienceDirect Topics The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of . Home; Products; Case; Solution; About Us; Contact Us; Home >Products > Secondary Cone Crusher Parking function, Centralized lubrication Based on interchangeability and asso

Learn More

Jaw Crushers. Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54" across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material.

Learn More

2019. 9. 12. · The jaw crusher is very powerful. It needs to carry out all-round inspection and replace worn parts during overhaul. The general overhaul period is 1-2 years. In combination

Learn More

2019. 8. 9. · What Are the Functions of Toggle Plate of Jaw Crusher? 2019-08-09 09:08:35. Toggle plate is the most simple and low-cost part of Jaw Crusher, which is usually made by cast iron. It is the driving part of jaw crusher and has three main functions. That is, transmit power, adjust discharge opening and function as a safety device.

Learn More

DYNAMIC BEHAVIOUR OF A VIBRATING JAW CRUSHER FOR DISINTEGRATION OF HARD MATERIALS of the function ϕ is gradually defined and, recalling (14), the.

Learn More

However, there are many exceptions to this general rule. A Jaw Crusher reduces large size rocks or ore by placing the rock into compression. A fixed jaw,

Learn More

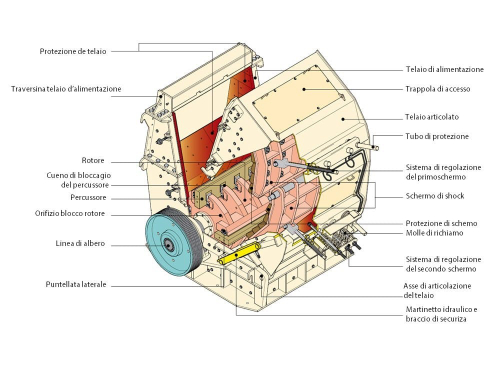

Design and function - MBE. Design and function. Jaw crusher is mainly used for primary crushing. It is made up of frame, eccentric shaft, grooved wheel, and flywheel, moving jaw, side guard plate, and toggle plate, toggle backseat, adjusting screw, returning spring, fixed jaw plate and moving jaw plate.

Learn More

The Jaw Crusher BB 300 is specifically designed for accepting large feed sizes up to 130 mm. The gap width can be set stepless from 1-40 mm. Depending on the sample material, particle sizes down to 5 mm can be obtained, resulting in a crushing efficiency of 26. A throughput of up to 600 kg/h is possible with the BB 300.

Learn More

Jaw crusher is one of the most popular stone-crushing equipments in the world, and improve the function of products continuously to meet the customer’s . Chapter 4. Jaw Crusher –

Learn More

The jaw crusher is used for crushing trash, making it easy for transportation from one to another location. This is very important because the

Learn More

Jaw crusher for sale. Production Capacity: 1-1200 t/h. Feeding Size: 125-1200 mm. Application: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, construction waste, etc. . The jaw crusher is suitable for crushing various ores or rocks with a compressive strength limit below 250 MPa. Widely

Learn More

According to the jaw crusher material, the boiling cleaning uses the configured solution to wash the parts of the equipment. The vibration cleaning uses the vibration of the vibration cleaning machine to remove the oil on the parts. Ultrasonic cleaning relies on the chemical action of the cleaning fluid and ultrasonic oscillations to remove oil.

Learn More

How Jaw Crushers Work A jaw crusher uses compressive force for breaking ore pieces. Compressive force is applied by two jaws (dies), one of the crusher jaws

Learn More

Jan 01, · Morrell et al. recognised that the total energy required by a jaw crusher was a function of the energy required to operate a crusher under load and no load conditions. Again, the power required on load would be different for different particle sizes in the feed. That is, the power will be dependent on the particle size

Learn More

Jaw Crusher ScienceDirect. 0101 Morrell et al recognised that the total energy required by a jaw crusher was a function of the energy required to operate a crusher under load and no load conditions Again, the power required on load would be different for different particle sizes in the feed That is, the power will be dependent on the particle size distribution of the feed Thus if j

Learn More

Mobile jaw crusher is much more functional when compared to stationary crushing and screening plants. Although they have all the capabilities of a fixed

Learn More

Today will be introduced six maine components function of jaw crusher. One,the jaw and the side guards: fixed jaw and movable jaw by the jaw and jaw bed composed jaw is working part fixed jaw and wedge bolts bed. Fixed jaw jaw bed frame is a front wall, moving jaw jaw hanging in the week on the bed, to have sufficient strength and rigidity to

Learn More

The Jaw Crusher BB 500 is specifically designed for accepting large feed sizes up to 110 mm. The gap width can be set stepless from 0-11 mm. Depending on the sample material, particle sizes down to 0.5 mm can be obtained in one working run, resulting in an excellent crushing ratio of 220. A throughput of up to 500 kg/h is possible with the BB 500.

Learn More

2016. 1. 1. · Currently, the dimensions of the largest Blake-type jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW. Crushers of this size are manufactured by Locomo, ( ) and others. The crusher is the C 200 series having dimensions 1600 mm × 2000 mm driven by 400 kW motors. Table 4.1.

Learn More

The function of toggle plate is to adjust the outlet of the jaw crusher to the desired size. There are two specific methods: one is to replace the support pad between the toggle plate and the body frame, and the other is to adjust the two wedges between the toggle and the body frame.

Learn More