-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

Today, we will talk about the solutions of lubrication fault of cone crusher. High temperature of lubrication oil. 1. The cooling fan does not work; 2. The heat dissipation of cooling fan is bad; 3. The inner parts are burnt; 4. Safety valve invalid. Low lubrication oil flow. 1. The oil filter is blocked; 2. The suction capacity of oil pump

Learn More

The lubricating oil goes into the cone crusher by two paths. One goes in from the bottom oil hole of cone crusher, and then divides into three directions to the inside and outside of the hollow eccentric shaft, the middle oil hole of the main bearing and the bowl type bearing, going through the hole lubricating big and small gear, and then the oil will return from the bottom oil returning hole

Learn More

Cone Crusher MP1250 · Hydraulic-Hydraulic Power Unit · Frame · Lube System-Main Reservoir · Gear-Drive · Grease Points · Drive Components-Coupling · Bearing · Privacy

Learn More

17/04/2022 · Jai Hind,about this video,cone crushe lubrication system.cone crushe oil circulationcone crushe lubrication system me kon kon se safety device lage rahten ha

Learn More

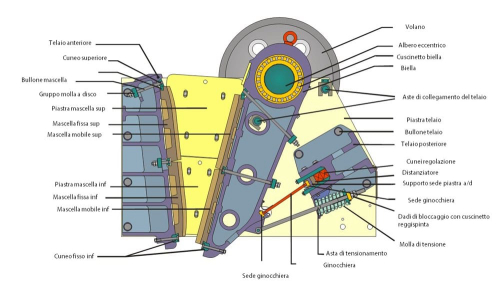

29/06/ · There are three main types of crushers – jaw crushers, cone crushers and impact crushers. Jaw crushers: In jaw crushers, a large feed opening receives material. There are two

Learn More

oil used for cone crushers - Grinding Mill China 7'0" cs series Oil tank Length 1000mm Width 1400mm Height 1700mm cone crusher, cs series 4800, grease lube point jaw crusher telsmith. oil coolinng system for cone crusher - Coal Crushing plant

Learn More

The actual crusher can be in the form of a cone, gyratory, impact, jaw, etc. For crusher systems that use oil lubrication for example, contamination of

Learn More

22/04/ · Under normal oil temperature, the hydraulic oil of the crusher has various s. Excessive oil temperature will cause many adverse effects on the hydraulic system, such as reduced viscosity, thin lubricating oil film and easy to be damaged, poor lubrication , low volumetric efficiency of the crusher, increased mechanical wear, accelerated aging of

Learn More

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn More

Crusher Lubricant™ ISO 150 D-A Crusher Lubricant™ provides excellent performance in gyratory, cone and jaw crushers. It is also well suited for use in screen gearboxes and bearings requiring EP gear oil lubrication. D-A Crusher Lubricant™ is specially formulated to be compatible with bronze and brass bushings and bearings.

Learn More

08/02/ · How a Gyratory Crusher Lube System Works: Certain components in the crusher (pinion shaft and bearings, pinion and eccentric gears, eccentric bushing, and st

Learn More

25/07/ · The second group of crusher components consists of the Cone Crusher’s oil system, the Cone Crusher’s dust seal and the thrust-bearing. The oil system, like the one used

Learn More

Cone Crusher Maintenance. How often should I change the lubrication oil? For a new crusher, change the lubrication oil after 100 hours of operation.

Learn More

capacity technologically advanced, mid-range cone crushers crusher lubrication system for Oil flow. Oil pressure. Oil tank temperature. Oil level.

Learn More

What is the working principle of the Cone Crusher? a common mistake to run an oil-lubricated crusher with contaminated lubricant (used oil, dirty oil).

Learn More

Crusher ; Client: Minera El Tesoro – Sierra Gorda ; System: Svedala H6000 Cone Crusher, Main Lubrication System ; Oil: 250L ISO 150 ; ISO Prior to CJC®: 18/15/11

Learn More

A lot can be learned about a cone crusher by simply watching the supply oil temperature and comparing it to the return oil temperature. Return oil temperature should be in the range of 60~140ºF (15~60ºC), although ideally in the range of 100~130ºF (38~54ºC). In addition, oil temperature should be monitored frequently throughout the shift.

Learn More

The oil temperature in the tank must be a minimum of 16 C (60 F) before the lube pump is started to prevent overloading of pump and motor assembly. However, to

Learn More

The lubrication system is an indispensable device for each crushing machine to ensure the good lubrication of the equipment and provide the crushing work for the cone crusher. condition. How the lubrication system works. The pressure oil from the lubricating oil station is divided into two paths before entering the cone crusher.

Learn More

Poor quality of lubricating oil. Poor oil quality will reduce the viscosity of

Learn More

Which oil is best for your Cone crushers CH/CS CH430? Complete professional advice, including motor oil, gearbox oil (transaxle) and lubricants for the power steering system, brake

Learn More