-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

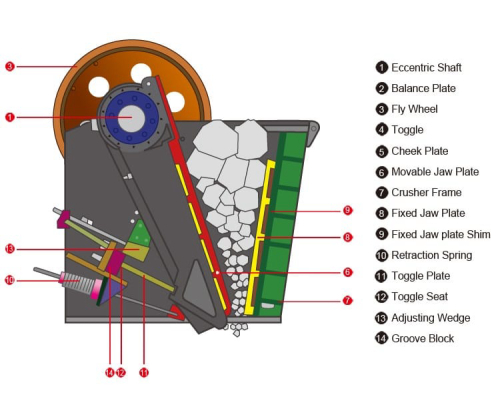

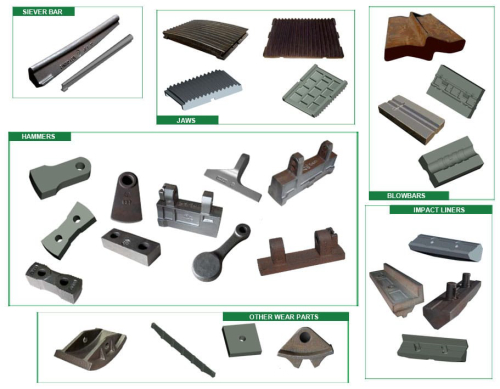

The sides of the crushing chamber are protected with cheek plates on the left side (1103-0) and right side (1104-0). Since these are exposed to high pressure and heavy wear (especially in the lower part of the crushing chamber), they are replaceable. Exchange a cheek plate when there is an obvious cavity in it (especially in the lower part).

Learn More

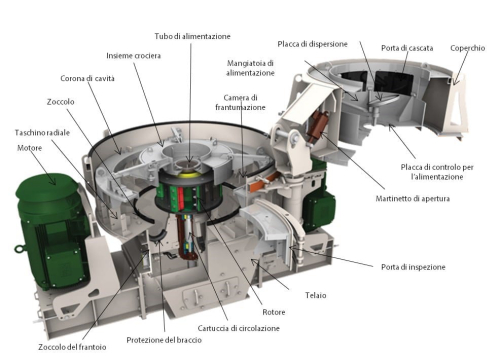

Cone crusher Cone crushers. The crushing chamber is designed to accept a constant feed of suitable material for all round crushing and self-breaking,

Learn More

Rock-Box Spider Cap & Arm Liner · Crushing Chamber Optimization · Wear Parts Optimization · Crusher Perfomance Reporting & Consulting · Mounting

Learn More

Crushing Chambers - Cones Having a good understanding of your crushers helps you make smart, informed decisions. Whether you want to build up your knowledge or refresh your memory, this is the place to start. We take you through the basics of cone crushing to more detailed advice on chamber solutions, feed arrangements and configurations.

Learn More

All chambers are engineered to be the perfect fit for your application. IMPORTANCE OF CONCAVE SELECTION The crushing chamber is mostly determined by the concave (or outer liner) selection. We offer between four and eight different standard concaves per crusher model, each of which has a specific application area.

Learn More

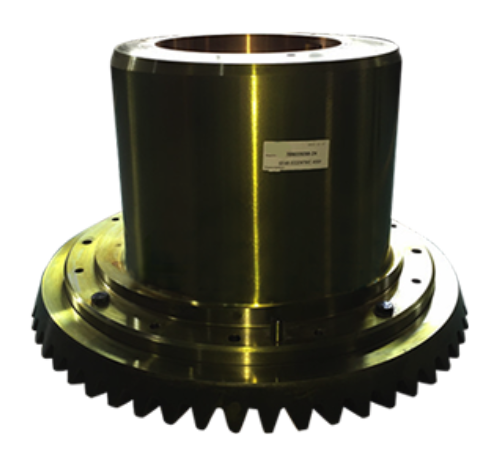

SUMMARY OF THE INVENTION: The crusher's working space consists of a receiving zone and a crushing chamber formed by the linings of a crushing cone 1 and a crushing bowl 2. When the crusher operates, the material from the receiving zone enters the crushing chamber, is clamped between the linings and is destroyed by mutual grinding and splitting of particles due to

Learn More

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, The volume or cavity between the two jaws is called the crushing chamber.

Learn More

Flexible crushing chamber options. Modular oil system includes 160 liters(42 gallons) oil tank, gear pump, relief valves for low pressure oil circulation and high pressure lid lifter circuits, low flow rate shut down switch, oil heater, oil level gauge, oil temperature and lube oil pressure gauges

Learn More

Translations in context of "crushing chamber" in English-Chinese from Reverso Context: 1, Feed, crushing chamber, can adapt to block material, the materials

Learn More

2022. 9. 2. · Techroq's rock-on-rock crusher pumps dry stone at high velocity, launching an uninterrupted rock stream into a stone lined crushing chamber. The rock lined rotor accelerates the feeding rate into the machine, with materials dischardged into the crushing chamber at high velocity - up to 85 meters (275 feet) per second.

Learn More

The crushing chamber of the cone crusher that is optimized and reformed adopts the lamination crushing principle and designed as the trapezoid structure. At the same time, the materials can be kept on the upper part of the crushing chamber for a

Learn More

The utility model discloses a crushing chamber of a crusher in the field of cereal and feed machinery. The crushing chamber comprises a casing, a feed inlet and two screen plates, wherein a rotor is horizontally arranged inside the casing and includes a spindle, a plurality of hammer carrier boards and hammer plates, the hammer carrier boards are perpendicular to axis of the

Learn More

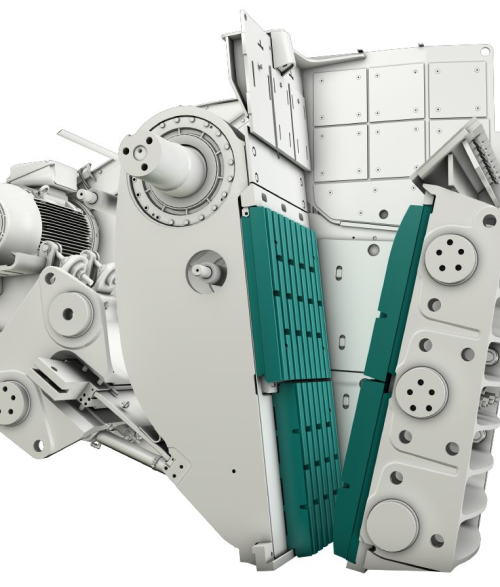

Fore more information about our range of jaw crusher wear parts and liners, contact our team today. Long Crushing Chamber. The long crushing chamber featured

Learn More

the crushing chamber. As illustrated in Figure 4, the three commonly used cone crusher chamber geometries fine, medium and coarse result in different

Learn More

We take you through the basics of cone crushing to more detailed advice on chamber solutions, feed arrangements and configurations.

Learn More

To make sure that your crusher is delivering the desired product, and maximizing its efficiency and productivity, there are a few potential issues that you should be alert to. At we have researched the factors that - if not properly addressed - can cause cone crushers to perform below their optimal level. Crushing chamber selection

Learn More

2020. 4. 27. · Read Crushing Chamber Application Guide C5-1086:01ENG by sandvik9 on and browse thousands of other publications on our platform. Start here!

Learn More

The Washington County Chamber of Commerce in Hillsboro, Oregon provides you with the tools and knowledge you need to reach your goals. 5193 NE Elam Young Parkway, Ste A Hillsboro, OR 97124 503.648.1102

Learn More

Full crushing chamber. This means that cone head must be covered by rock. Stable and continuous feed. Material below setting in the feed 10-30% (but no filler and fines 0-4 mm normally). Maximum feed size. Reduction ratio must be limited to 3 (-4). Recommended max feed size is 50 mm. Correct feed distribution.

Learn More

The bisector line of crushing chamber is vertical at the inlet of crushing chamber and slants gradually from inlet to outlet. Feed material at upper part of

Learn More