-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

Stationary Cone Crushers Market Research Report is spread across 113 Pages and provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

Learn More

automax 1000 cone crusher max feed size – Grinding Mill China. OPS Screening & Crushing Equipment. Jaques World Class 42×30 Jaw Chamber. 650mm max feed size. up to 500T per hour. Gulin Finlay C-1540 Cone Crusher Automax 1000 .

Learn More

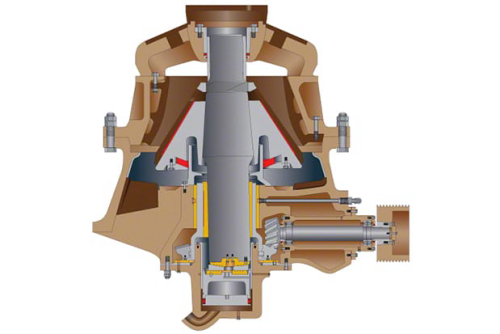

On the contrary to cone crushers, gyratory crushers have a small cone angle, which locates the contact zone between particles and crushing elements at an upper area of the chamber, not at the bottom. This implies that the limited number of comminution events (1 single rock probably will get at most 2 strokes before exiting the gyratory) in a

Learn More

Cone crushers are often referred to as secondary crushers as they are responsible for sizing the material to more specific sizes The material is reduced to

Learn More

Cone crusher size reduction control (Itävuo et al., , Itävuo et al., ) was realized using a discrete-time I controller 2 in velocity form (Åström and Hägglund, 2006) to avoid the undesirable process upsets in case of measurement errors and measurement noise.

Learn More

26/02/ · Referring to the table which lists percentages of product passing an equivalent square opening, we find that 85 to 90% of the crusher product should pass a 3.5″ square

Learn More

Jaw crushers are sized based upon the dimensions of the top feed inlet (gape) or the dimensions of the jaws. For example, a 32 x 54 sized jaw crusher will

Learn More

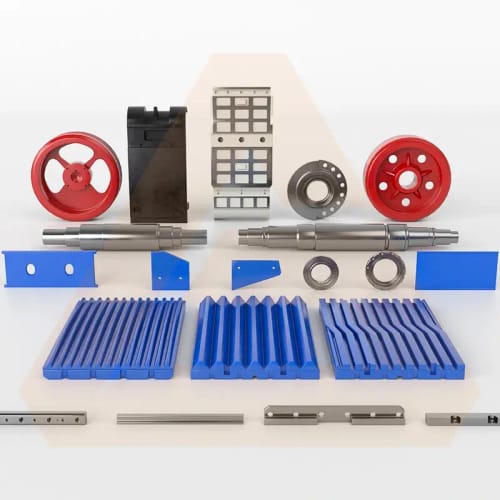

DYNAMIC EQUIPMENT CONE CRUSHER RANGE ; DYNAMIC SPRING CONE CRUSHER · Sizes available: 2ft; 3ft; 4ft & 4 1/4ft; 5 1/2ft; 7ft ; DYNAMIC HIGH CAPACITY CONE CRUSHER.

Learn More

Depending on the specific cone crusher, the maximum feed size is up to 300 mm, resulting in a finished product with a grain size of between 3 mm and 60 mm

Learn More

On the contrary to cone crushers, gyratory crushers have a small cone angle, which locates the contact zone between particles and crushing elements at an upper area of the chamber, not at the bottom. This implies that the limited number of comminution events (1 single rock probably will get at most 2 strokes before exiting the gyratory) in a

Learn More

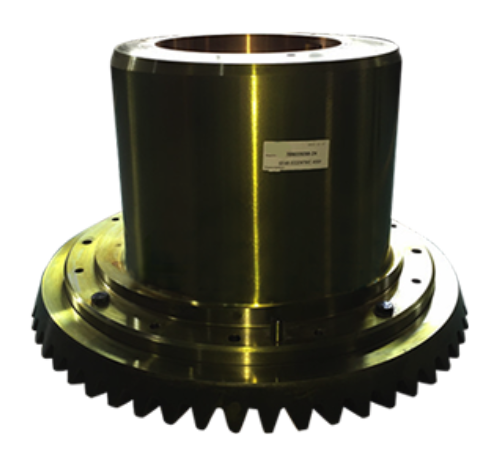

Cone crushers come in a variety of sizes. Large ones can weigh as much as 95,000 kg creating 750kW of crushing power.

Learn More

How to improve the output of cone crusher is very important. The crushing output of the cone crusher can be adjusted by adjusting the size of the closed side discharge opening. The smaller the size of the closed side discharge port, the smaller the output of the cone crusher, and the better the quality of the finished material discharged.

Learn More

1a). The size reduction process in a cone crusher, on the other hand, evolves like a series of crushing events. It simply occurs by the rotation

Learn More

19/07/ · Multiply the product from step (9) by the tons per hour to obtain the gross hp required. Cone Crusher Motor Sizing Hard limestone, having an impact strength of 15, is fed

Learn More

11/02/ · A crusher should be operated above 40% but below 100% rated horsepower in order to maximize cone crusher productivity and to have a proper “loaded bearing alignment”. An

Learn More

Avoid scams, deal locally Beware wiring (e.g. Western Union), cashier checks, money orders, shipping.

Learn More

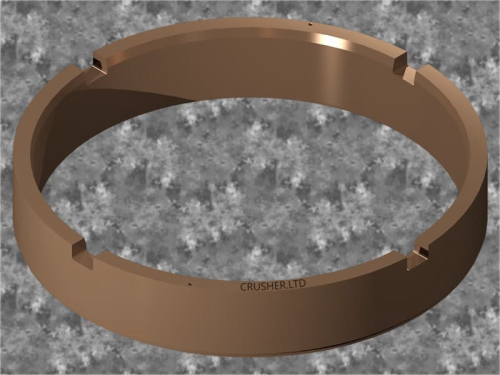

Cone crushers are only altered in the space between the mantle and side. These settings are called the OSS (open side setting) and CSS (closed side setting.) The gap on the side that is open determines the size of the largest particle of the finished product.

Learn More

29/05/2022 · Cone crushers can be altered in the space between the mantle and the side. These settings are known as the OSS (open side setting) and CSS (closed side setting.) The size of the largest particle in the finished product is determined by the opening on the side that is open.

Learn More

0183 32 cone crusher concave and mantles are the main factors that determine the size of the discharge opening when the cone crusher is under load, concave,

Learn More

20/07/2022 · The following is a detailed description of the discharge control modes of jaw crusher, impact crusher, cone crusher, hammer crusher and roller crusher. Jaw crusher. It is a common coarse crusher. The size of the discharge port determines the size of the crushed stone and the production capacity of the equipment.

Learn More

03/06/ · A first-stage crusher, such as an impact or jaw crusher is used to break raw material down to a size that the cone crusher can accommodate. Cone crushers are typically looked at

Learn More