-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

JAW CRUSHERS. Applications: Primary. Industries: Aggregate, Mining, Recycling. Mounting: Portable Plant, Mobile Plant, Skid,. Stationary, Bare.

Learn More

GreyHawk/ C3054 Portable Jaw Plant. The C3054 is an efficient primary jaw crusher for quarries, gravel pits, mines and recycling. Mounting of the crusher is made without a bolted connection

Learn More

Jaw Crusher Installation Operation – Free Articles Directory Jaw Crusher is generally installed above the concrete foundation. Given the weight of a larger

Learn More

Jaw Crusher Installation Points. 1, equipment to lay the foundation. The jaw crusher is usually installed on a concrete foundation with a drain tank on the

Learn More

Mounting the crusher does not require anchor bolts. This is due to our unique solution where the crusher is standing on its own weight, and vibrations are absorbed by rubber dampers under support brackets. They are also engineered to deliver the maximum productivity at the lowest operating costs. Modular design enables easy installation Mining

Learn More

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

Learn More

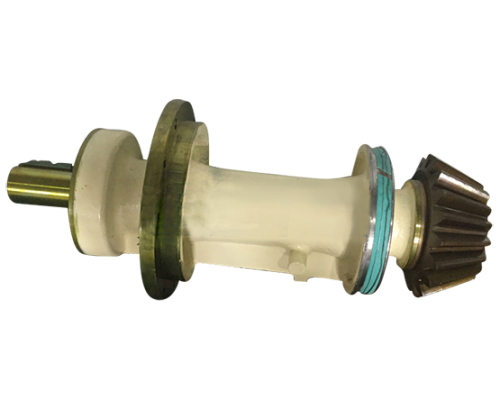

The Design of Rolling Bearing Mountings. The bearings are mounted on the shaft with adapter sleeves FAG H3260HGJ and FAG H3176HGJ, re-spectively , Bearing mounting of a double-toggle jaw crusher Locating bearing Floating bearing Swing jaw Eccentric shaft Pitman 93 Hammer mill Hammer mills are mainly used for crushing ores, coal, and stone

Learn More

CRUSHER MOUNT GR-1031 ; Minimum Order Quantity, 36 Number ; Usage/Application, jaw crusher ; Material, Natural Rubber ; Packaging Type, Box ; Shock Proof, Yes.

Learn More

Since the jaw crusher is vibrating during operation, the machine should be installed on the concrete foundation. In order to reduce vibration,

Learn More

Mounting of the crusher is made without a bolted connection to the foundation. The main frame of the crusher is made of rolled steel side plates and two steel castings, connected through precision machined bosses and held together by large diameter bolts.

Learn More

A generally horizontal flow vertical axis jaw-type crusher is provided wherein the jaws are mounted for eccentric motion toward and away from each other and

Learn More

How to Properly Install and Use Jaw Crusher ?】 What is jaw crusher for? Jaw Crusher is a kind of mining equipment used for primary and secondary crushing.

Learn More

A method for mounting a jaw die plate of a jaw crusher detachably against a front end wall of the crusher by means of a fastening device operated from outside a side wall of the crusher. The die plate is secured in its place by means of friction between the fastening device and a counter surface of the front end wall and friction between the

Learn More

Jaw crushers are the workhorse of the crushing industry for mining, construction, and demolition recycling. Mt. Baker Mining and Metals' jaw crushers are industrial grade, continuous duty machines. They take large pieces of rock, ore, concrete, or other materials, and crush them down to smaller sizes, for further processing in a ball mill or hammer mill, or for use in ballast or fill

Learn More

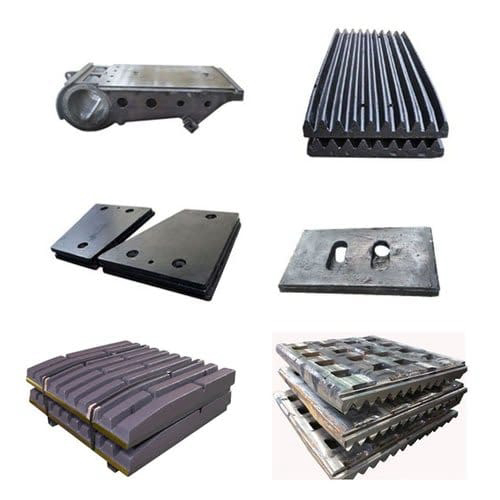

Jaw Crusher is consists of many parts, like eccentric draft, frame, large belt wheel mobile jaw crusher, flying wheel, toggle jaw plates, gap adjustment screw and so on. The main function of Jaw Crusher is to crush large rocks into smaller rocks, gravel, rock dust and gravel to satisfy different requirement for the products.

Learn More

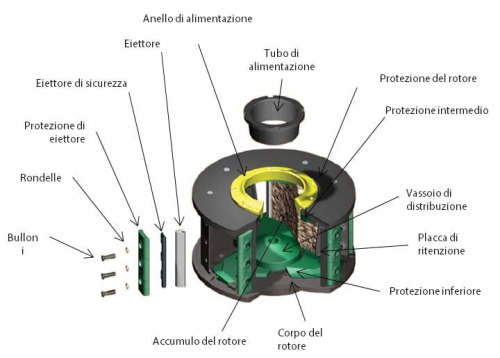

Wash the upper and lower bearings of the rod bolt and lubricate them with thin oil, and then install the bearing, main shaft, upper bearing, and

Learn More

The movable jaw of the jaw crusher is assembled by preassembled movable jaw parts. First, Assemble the movable jaw parts accordingly. The movable jaw, movable

Learn More

Jaw Crusher Primary Jaw Crusher Secondary Jaw Crusher Tertiary Jaw Crusher Mobile crusher Skid Mounted Jaw Crusher.

Learn More

BOND Crusher mounts are used in Stone crusher, Jaw crusher, Impact crusher Cone crusher etc. The crusher mounts are made as per requirement of individual

Learn More

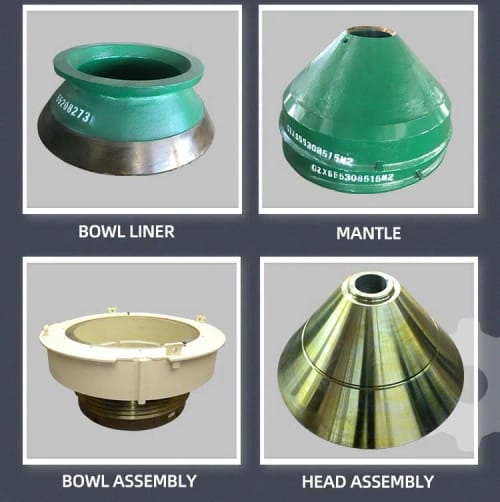

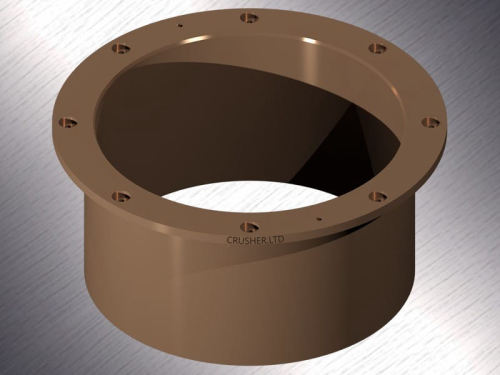

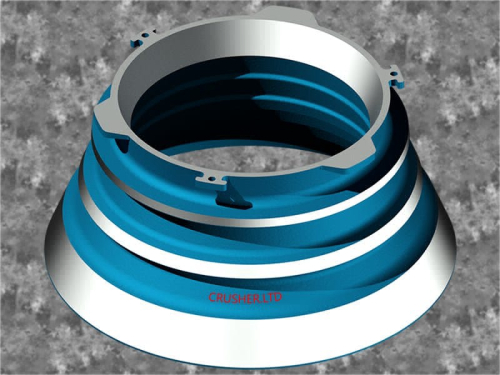

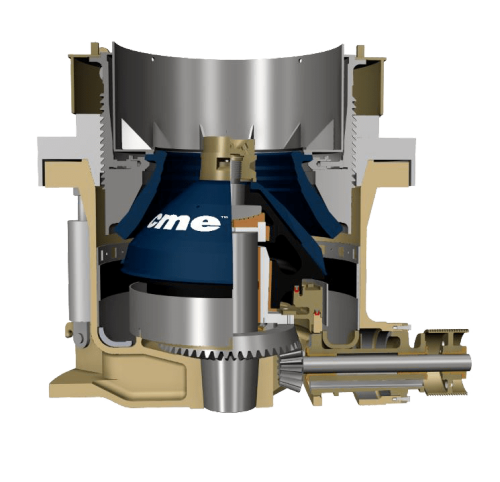

Aug 28, · Jaw crusher crushes on half-cycle and favors arrested crushing. The fixed jaw crusher foundation needs to be rugged to overcome the working stress. For gyratory crusher, the outer circle represents the stationary bowl covered by the concave and the inner circle represents the main shaft covered by the mantle.

Learn More

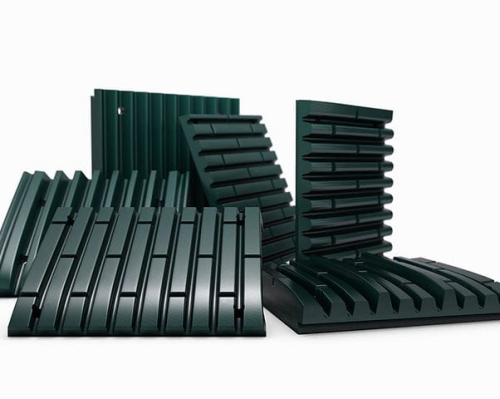

In a large size jaw crusher for stones and the like a stationary housing wall and a pitman are each provided with a pair of endwise aligned die plates. Sets of mounting bolts secure the die plates, respectively, to the housing wall and pitman, and each pair of die plates is provided with an interlocking finger joint across its width. The interlocking finger joint couples the endwise

Learn More