-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

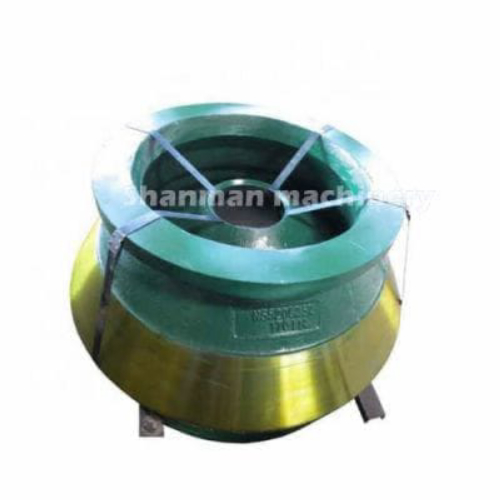

Cone Crusher Liners — find the correct solution for your application. Using our knowledge as an Original Equipment Manufacturer (OEM), we ensure that the supplied product is correct for your equipment and application. We offer Cone Crusher Liners tailored to your needs and manufactured to help you find increased productivity.

Learn More

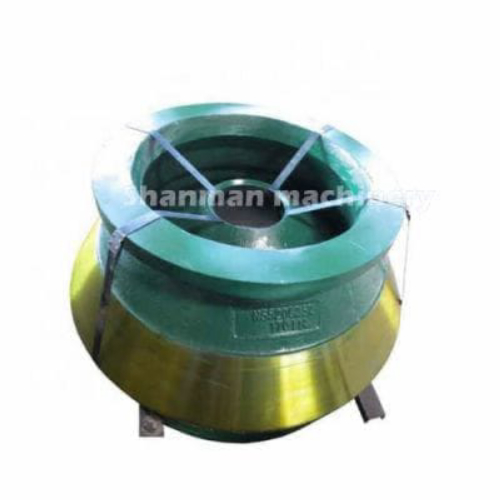

2.Crusher Liner’s Material. Cone crusher wear parts, concave and mantle, are casting by manganese steel. Mangalloy, also called manganese steel or Hadfield steel, is a steel alloy

Learn More

The most important factor in Cone Crusher liner selection is the feed. Cone Crusher Cavity Types. You should have a well-graded feed going into the crushing chamber. A well-graded feed is generally considered as: 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two.

Learn More

23/06/ · When you see a 10% or more drop in production level or throughput, it is a good indication the Cone Crusher liners need to be changed. 2. Liner thickness. If the liner is

Learn More

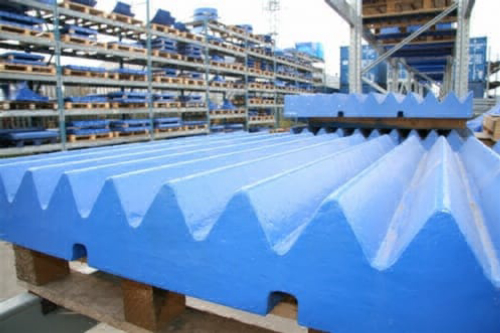

Liner thickness Depending on the application, If the Cone Crusher liner is wearing evenly throughout the chamber, when it has worn down to about 1" (2.5 cm) thick at the bottom it is generally time to consider changing it. At about 3/4" to 5/8" (1.9 cm to 1.6 cm) thick, the liner will crack, causing the backing material to begin to disintegrate.

Learn More

In the ore crushing and screening industry, there are not many choices for cone crusher liners. Most of the manufacturers don't offer this kind of wear parts, instead of relying on external foundries. Rayco is a leading casting manufacturer and supplier at home, able to offer high-quality chamber bushing options for various cone crushers

Learn More

We manufacture MP® cone crusher liners. A large copper mine in South America contacted us for assistance with their pebble crusher. The mine operates a MP

Learn More

China Mining Machinery Cone Crusher Parts High Mn Casting Cone Crusher Liners, Find details about China Cone Crusher Parts, Cone Crusher Liners from Mining Machinery Cone Crusher Parts High Mn Casting Cone Crusher Liners - HENAN CRUSHTECHS MACHINERY CO., LTD.

Learn More

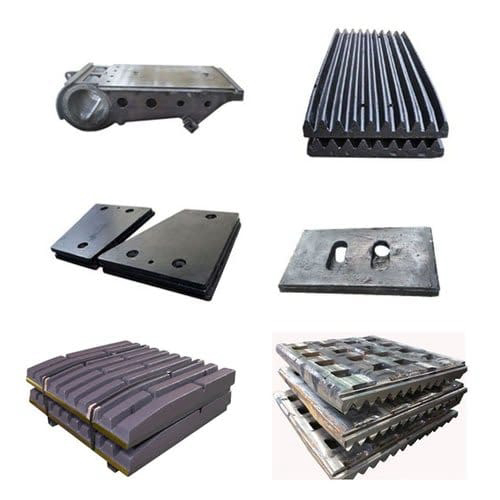

Our CSP Crusher wear liners offering covers major gyratory crushers, jaw crushers, cone crushers, impact crushers and roll crushers – optimized for any size

Learn More

The secondary crushers are designated as Standard cone crushers having stepped liners and tertiary Short Head cone crushers, which have smoother crushing faces and steeper cone

Learn More

HENGIN'S OEM Crusher Spare Parts products include hydraulic cone crusher, jaw crusher, gyratory crusher main frame, adjusting ring, copper sleeve, bearing,

Learn More

Cone Crusher - CEC SC300 Nixon-Egli Equipment Company. CEC SC-300 Cone Crusher Ultimate speed cone Dual eccentric stroke Revolutionary manganese locking system lets you change the liner in two hours 50° head angle Very .

Learn More

Cone Crusher Liners - Manufacturers, Suppliers, Factory from China. We have state-of-the-art tools. Our products are exported towards the USA, the UK and so on, enjoying a fantastic reputation amongst customers for Cone Crusher Liners, Qms Blow Bar, Hammer for scrap metal recycling industry, Crusher Toggle Plate, Ceramic Crusher.

Learn More

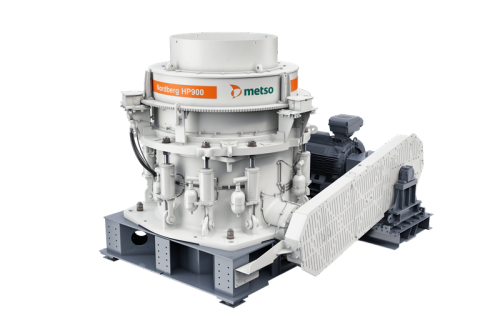

Brief Introduction. MP CC and CC-S Cone Crusher applies material selection crushing technology (MSCT). The crushing chamber is designed to accept a constant feed of suitable material for all round crushing and self-breaking, which helps to reduce excessive wear of the liners. The MP Cone Crusher is advanced in design, more compact with a higher

Learn More

14/08/ · Cone crusher liner-replacement. When the liner of the cone crusher is not worn to the extent that it needs to be replaced, the tooth plate can be turned around, or the upper and lower parts can be turned around. When the thickness of the liner of the cone crusher reaches 65% to 80%, or the partial wear is deformed and broken, it should be replaced.

Learn More

Durable cone crusher wear parts - bowls and mantles, liners, torch rings, and distributor caps engineered to exceed OEM wear life performance.

Learn More

27/12/ · The feed is the most crucial factor to consider when choosing a Cone Crusher liner. The Cone Crusher liner should have a well-graded feed flowing into the crushing chamber.

Learn More

Cone crusher liners D Series 367s. USED. Manufacturer: Telsmith. D Series 367s Gyrasphere Cone Crusher $70,000 CAD + applicable taxes & fees Coarse Concave and STD Mantle Can Receive 7-inch Rock When New & 5-inch Top Size When Liners Are Worn Manual Screw Adjust For C $54,034. Sunnyside, Manitoba, Canada.

Learn More

Cone Crusher Liners Makuri provides real solutions for cone crusher liners that go above and beyond the usual OEM standard profiles, leading to measurable improvements and lowest TCO every time. Secondary Crushers Optimized secondary crushing improves overall plant throughput and reduces TCO.

Learn More

Cone crushers operate by having stone fed into the top of the crusher chamber. The chamber is lined with wear parts, namely the mantle and bowl liners.

Learn More

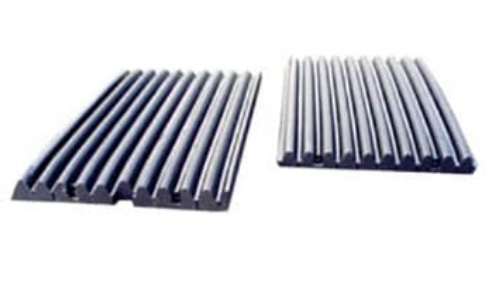

FEATURES & BENEFITS OF OEM JAW LINERS · 18% Manganese supplied as standard provides results across the broadest range of applications · A range of tooth profiles

Learn More