-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

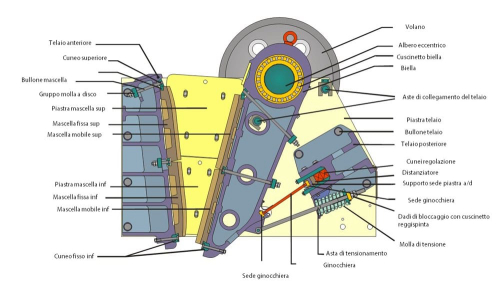

Because the jaw is pivoted at the top, the throw is greatest at the discharge, preventing choking. Crushing angles in standard Allis-Chalmers-

Learn More

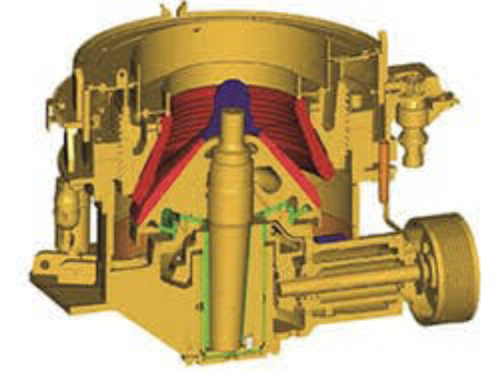

A higher eccentric throw means fewer crushing zones, so the journey through the crusher is quicker. The quicker the journey through the crusher, the greater its

Learn More

consumption of a jaw crusher are toggle speed, throw and reduction ratio. These parameters were varied during the simulation

Learn More

Mobile Jaw Crusher Closed Side Setting css Range. Measuring the closed side setting css or open side setting oss is usually confusing as many methods are employed without understanding consequences css is the smallest discharge opening dimension on the jaw oss is the largest discharge opening dimension on the jaw it is equal to the css plus the throw of the swing stock the dimension on

Learn More

Adjusting eccentric throw on a cone crusher. adjusting eccentric throw on a cone crusher. easy stroke adjustment for gp300 cone crushers, it gyratory crusher eccentric throw. learn more. ch660 cone crusher construction. the crushers can easily be matched to changes in production selecting the right crushing chamber and eccentric throw .

Learn More

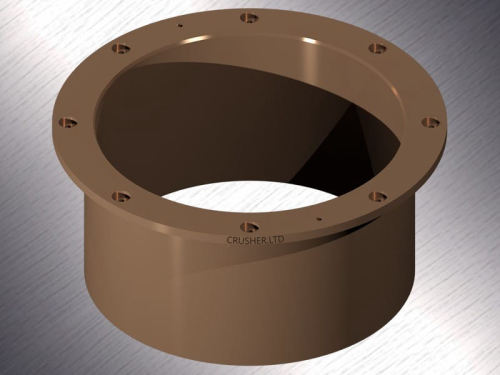

Our jaw crushers are fabricated with an extra-heavily ribbed steel plate construction to provide maximum strength and durability while in

Learn More

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn More

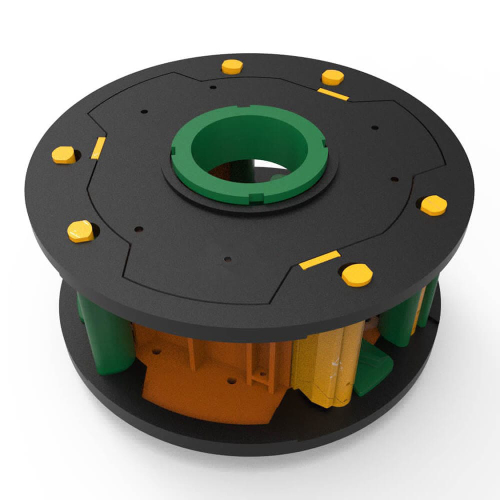

Both jaw crushers and gyratory crushers are still used today. The material is thrown back and forth between the plates and hammers until it is reduced

Learn More

The three main types of crushers are the cone crusher, the jaw crusher, and the impact crusher. Make sure you understand all of the differences between these kinds before choosing one for your project. Regardless of which type of machine you choose, you should be prepared for some very powerful crushing power. Make sure that anyone who is set

Learn More

Keywords: Design; Operations; Jaw crusher; Challenges; Crushing parameters eccentricity of the shaft leads to increase in throw; hence,.

Learn More

01/01/ · Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw). The faces of the plates are made of hardened steel. Air-dried

Learn More

The eccentric throw is one of the most important parameters in defining the job that your cone crusher does. The mantle in a cone crusher spins in conical pendulum motion. That means it

Learn More

throw crusher stones-throw crusher throw jaw crusher gyratory crusher cane crusher throw of an axis double pole double throw switch throw open Blake crusher

Learn More

PE Jaw Crusher For Sale; Capacity: 110-1100 t/h, Customized Max. Feeding Size: 125-1200 mm Compressive strength: Less than 320 MPa Processed Materials: Granite, marble, basalt, limestone, quartz, river pebbles, iron ore, copper ore, etc. Application: Widely used for medium-sized crushing of ore and bulk materials in mining, metallurgy, construction, road, railway, water and chemical industries.

Learn More

The maximum amplitude of swing of the jaw, or "throw", is determined by the type of material being crushed and is usually adjusted by changing the eccentric. It varies from 1 to 7 cm depending on the machine size, and is highest for tough, plastic material and lowest for hard, brittle ore.

Learn More

The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS. Throw = OSS – CSS.

Learn More

Jaw crusher,Ball mills,Cone crusher,Sand maker,Rotary kiln Gulin Machinery provides you Stone Crusher, Jaw Crusher, Vibrating Screen,Rotary kiln, Ball mills etc. diagram jaw crusher system conveyor – Crushing Plant. Engineering Products, Secondary Jaw Crusher, Offering Conveyor Systems, Hydraulic Conveyor Systems, Mechanical Conveyor

Learn More

This system results in a higher capacity than that achieved with a double-toggle jaw crusher with the same feed opening. Available in various sizes, they achieve throughputs of 250 t/h to 1,400 t/h. Double-toggle jaw crushers. Double-toggle jaw crushers are the ideal machines for the hardest and most tenacious materials.

Learn More

The horizontal component of motion (throw) at the discharge point of the single-toggle jaw crusher is greater than the throw of the Dodge crusher at that point; in fact, it is about three-fourths that of Blake machines of similar short-side receiving-opening dimensions. The combination of favorable crushing angle, and See more

Learn More

Contents · 1 Background history · 2 Industrial use · 3 Types of crushers. 3.1 Jaw crusher; 3.2 Gyratory crusher; 3.3 Cone crusher. 3.3.1 Compound cone crusher; 3.3

Learn More

18/02/ · All jaw crushers will have one fixed jaw and a moving one. These two form a V-shaped chamber, where the materials are fed. The movable jaw will move back and forth

Learn More