-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

China jaw crusher efficiency Manufacture, choose the high quality jaw crusher efficiency from China We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for jaw crusher efficiency we shall be additional than pleased to do so.

Learn More

New crusher improves quarry efficiency and operator safety. Dec 13, · New crusher improves quarry efficiency and operator safety. QI353 impact crusher has been built with more productivity, connectivity and safety at the forefront of its innovative design. has launched a new crusher, QI353, which is the most

Learn More

Webinar: Maximizing cone crusher efficiency using chamber. Jun 29, · Rather than only looking at production volumes, achieving a balance between capacity, end product size and crusher efficiency can bring the biggest gains in profitability. Common issues such as poor wear shape, ring bounce, power spikes, component failures and liner

Learn More

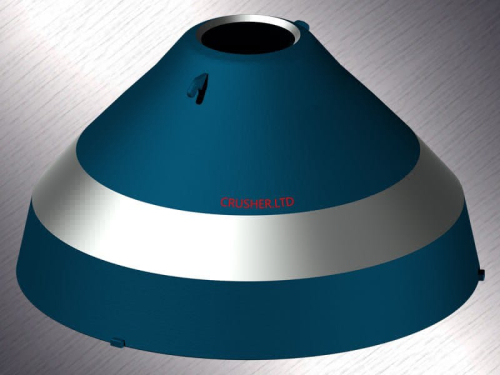

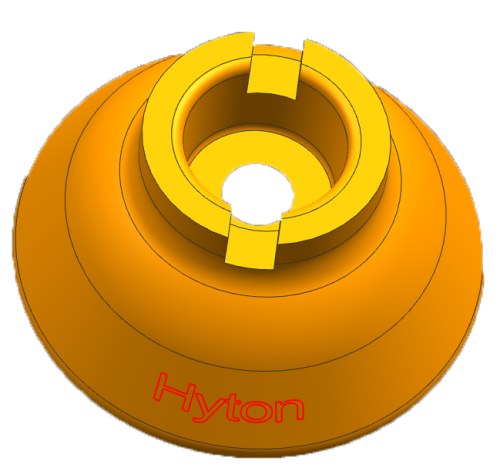

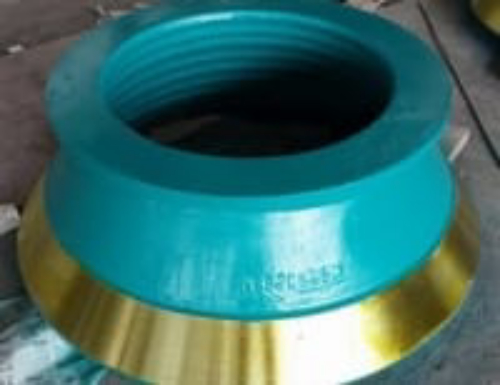

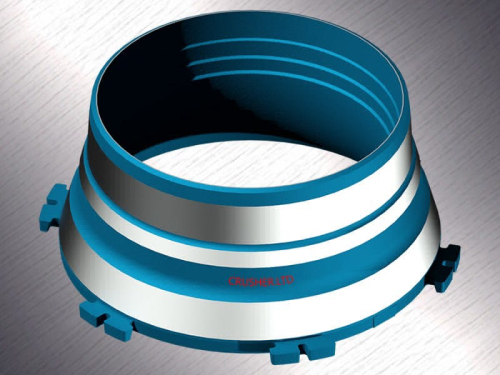

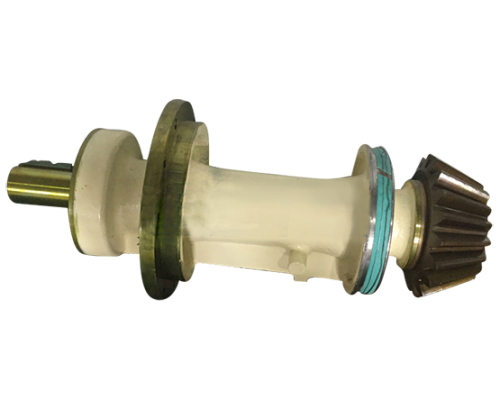

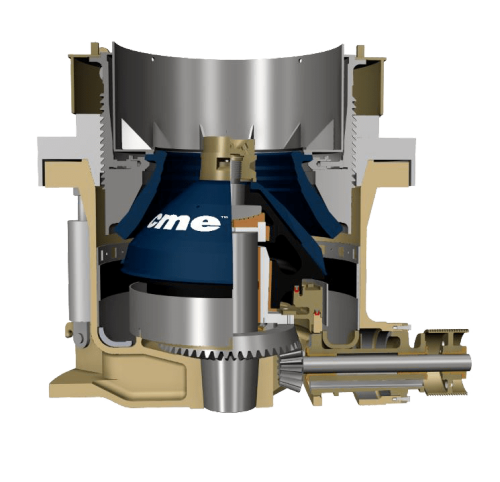

Cone Crushers. The benefits of high efficiency, greater crushing force and high capacity coupled with the durability the market expects are the reasons why this design is the best way to increase your productivity and profitability. Sleeve bearings make removal and installation of the MSP Cone Crusher head and main shaft simple.

Learn More

Efficient use of cone crushers A cone crusher is often used in the second to third crushing stage and operates according to the pressure crushing principle.

Learn More

High Efficiency Cone Crusher Laminated Large Capacity Crushing Than Cone Crusher , Find Complete Details about High Efficiency Cone Crusher Laminated Large Capacity Crushing Than Cone Crusher, Cone Crushers,Cone Crusher Reduction Ratio Cone Crusher Machine,Hot Sale Mining Stone Crusher Cone Crusher from Crusher Supplier or Manufacturer-Henan Aomite Technology Heavy Industry Co., Ltd.

Learn More

2022/9/7 · It is an efficient and popular primary crusher for granite. In addition, the fine crushing jaw crusher developed by can also meet the fine crushing needs of granite. Feeding size: ≤1, 200 mm. Discharging size: 10-350 mm. Capacity: ≤2, 200 t/h.

Learn More

9/1 · Fig. 12. Jaw crusher at ÅA Geology and Mineralogy laboratory and experiment rocks. The power consumption of the machinery is described as the electrical current consumption of a tri- phase motor. As the Bond theory (Eq. (2)) is based on shaft power consumption [4] an electrical efficiency value has to be considered.

Learn More

As the saying goes, if you want to have high work and study efficiency, you must raise your body, and the machine is no exception.

Learn More

Jaw Crushers for efficient primary size reduction The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and pre-crushing of mediumhard, hard,

Learn More

So, assembled our vertical crusher, your crushing efficiency will have a great improvement. Maximizing Screening Efficiency Efficiency = TPH of Undersize in feed which actually passes TPH of Undersize in feed (should pass) = 469 TPH (469 - 22 TPH) = 95.3 Calculate the efficiency of the 1" cut on the top deck. Calculating Screen Efficiency Example.

Learn More

12/20 · Crusher optimization improves production efficiency and reduces opex. The Outotec embedded crusher expert saw a number of ways to not only improve crusher availability, but also save significantly on operational expenses and improve efficiency. General optimization of the cone crushers involves finding the best balance between three set

Learn More

Minimize surge loading for a more efficient circuit. Surge loading has a bad effect on the production of any crusher. Surge piles or feed

Learn More

30% compared to crushers and screeners, offered by other manufacturers, who do not apply this technology. Hybrid diesel / electric drive options. Keestrack

Learn More

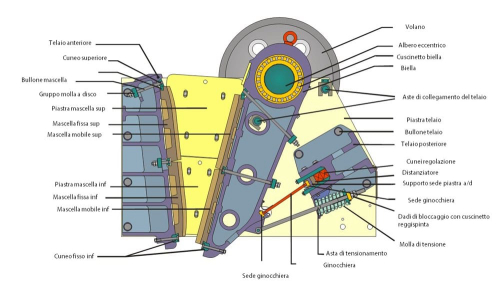

Compared with hammer crusher, the wear resistant parts have longer service time, high production efficiency and fewer maintain fees. The common jaw crusher has single toggle type and double toggle type, the former one also called as simple swing crusher, the latter one is called as complex swing crusher. 3. Gyratory crusher

Learn More

The parts of jaw crusher is a key to increase crushing efficiency, the wear resistance of the jaw more greater, the use life is longer, reducing the investment. Factors Affecting The Crushing Efficiency Of The Crusher. The production efficiency of the rock crusher has great influence on the efficiency of the whole crushing plant.

Learn More

It is well known and taken for granted that the efficiency of energy use by comminution (i.e. breaking, crushing, grinding) equipment is

Learn More

9/30 · A crusher is designed to work with the lube oil in the range of 10°-51°C. The maximum oil temperature is controlled by a sensor switch at the reservoir return line and if the crusher is used regularly in extremes of heat or cold and it is hard to maintain crusher oil in the correct operating range, it may be necessary to switch to synthetic oil.

Learn More

Impact Crusher- Heavy Industry - Crusher & Mill, Jaw Impact Crusher can crush many kinds of materials with max feed size less than 500mm and crushing strength less high efficiency, low consumption;

Learn More

One of the key aspects of maximizing crusher efficiency is to have a routine maintenance program for your equipment. This can help you keep all aspects in peak condition and avoid unplanned downtime. This includes scheduled checks and services that are recommended by the manufacturer of your crusher.

Learn More

Quarry rock of 12 in. maximum size is to be handled in a two-stage crusher plant at the rate of 70 tons per hour. The maximum size of output is to be 1½ in., and separation of materials over 1 in. size and the minus 1 in. in the output is required. Select a jaw crusher like those included in this table.

Learn More