-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

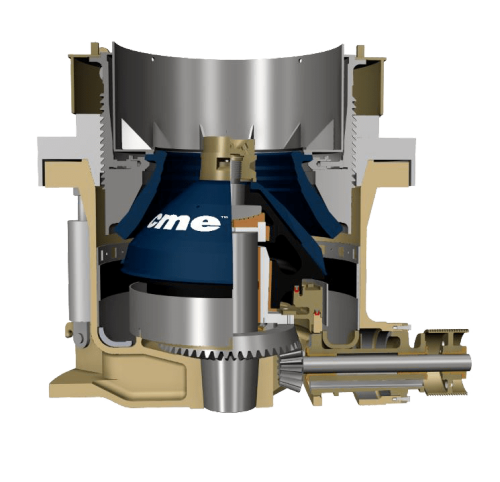

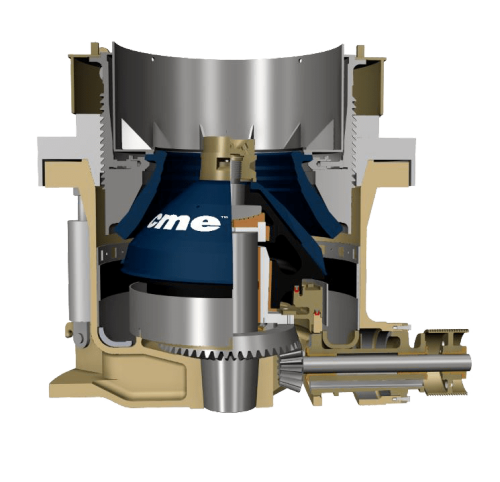

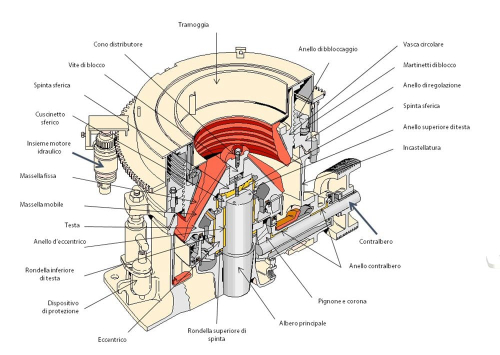

A cone crusher is similar in operation to a gyratory crusher, with less steepness in the crushing chamber and more of a parallel zone between crushing zones.A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating spindle, which is covered by a wear resistant mantle, and the enclosing concave hopper, covered by a manganese concave or a bowl liner.

Learn More

The Mobicone MCO 9i EVO/MCO 9i S EVO mobile cone crushers from Kleemann offer aggregate producers high-productivity secondary or tertiary crushing in a fuel-efficient, Tier 4 Final emissions-compliant machine. The S-version of the MCO 9i EVO provides a discharge conveyor-mounted final classifying screen with oversized aggregate return conveyor.

Learn More

Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from

Learn More

30/09/ · Ensuring efficient cone crusher operation can deliver major economies of scale for quarrying facilities There are a number of ways in which cone crusher throughput can be optimised. One of the key issues is in keeping the system choke fed during operation, as this maximises the effectiveness of rock-on-rock crushing, extends the wear life of manganese

Learn More

The CST Cone Crusher is a medium-to-large size, track-mounted crusher plant designed for secondary crushing of hard rock into cubical sizes. Featuring a heavy-built "quarry duty" cone crusher, the CST is perfect for rock quarries and other mining operations. View CST Mobile Cone Crusher CXT Mobile Cone Crusher

Learn More

1. Operate at a consistent closed-side discharge setting. · 2. Operate at a consistent “choke-fed” cavity level. · 3. Do not trickle feed the

Learn More

operation; no additional laboratory tests are required. K1 to K3 and the cone crusher operating parameters are given by:.

Learn More

Cone crushers, also referred to as gyratory crushers due to their gyroscopic motions during the size reduction process, were Grinding Operation-Grinder System Operating Principle Structure of Grinding Operation. The whole system of all grinding mills are same that consists of main frame, reducer, classifier, piping device, blower, primary jaw

Learn More

After making sure there is no problem in the above factors, test the cone crusher without load and then put it into production. 2. Check The Spare Parts. The service condition of bearings directly affects the service life and operation of cone crusher, so operators should ensure the good lubrication of cone crusher in the production process.

Learn More

This design has been proven to perform in heavy-duty secondary and tertiary crushing applications being tough, reliable, simple to operate and easy to maintain.

Learn More

One of the main elements of a cone crusher is a crushing cone (armor), the surface wear Concrete crumbles during the operation of cone crushers,

Learn More

Contact Now +86-13879771862. Published time:09 October 2019. Cone crusher is one of the most widely used mining equipment. This paper makes a description and comparison between the 5 types of cone crushers, to help you choose the right one. JXSC engineer team does help you to buy the cone crusher, and design a complete crushing circuit.

Learn More

21/03/ · The MX™ cone crusher is based on the patented Multi-Action crushing technology, which combines the piston and rotating bowl into a single crusher. The

Learn More

contributes to an improved understanding of quarrying operations and thus Jaw, cone, gyratory, and roller crushers operate.

Learn More

MHP Cone Crusher Easier Adjustment.jpg. Tramp release and Hydraulic settings. Easier Operation. MHP series is fitted with a forged high tensile main shaft

Learn More

The CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of

Learn More

leading crushing and screening equipments manufacturer in Korea.www.ywcrusher.co.kr

Learn More

Stone Cone Crusher Wear Plate Suit for T300 Spare. Stone Cone Crusher Wear Plate Suit for T300 Spare Parts, Find Details about Stone Cone Crusher, Crusher Wear Plate from Stone Cone Crusher Wear Plate Suit for T300 Spare Parts - Maanshan City Hyton Heavy Industry Technology Development Co., Ltd. HS Code: 84749000.

Learn More

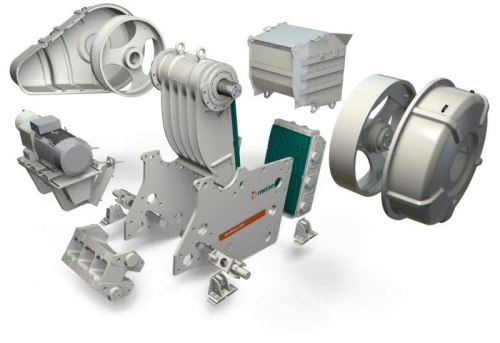

Our cone crusher parts are designed to the same specifications and standards as our cone crusher equipment, ensuring equipment compatibility for reliable and safe operation. Carefully produced at our own foundries We have complete control over quality at every step of the process, from the selection of raw materials to final production.

Learn More

The cone crusher is mainly used for secondary crushing and tertiary crushing in aggregate crushing of mines and quarries. Because of its strong crushing

Learn More

The operation procedure of cone crusher can be divided into four stages: before the start, at start-up, at run time and turning-off time.

Learn More