-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

The results of this thesis show a distrust towards vibration monitoring, while other means of condition monitoring such as lube oil and thermal analysis is common on board. This distrust can be related to the complexity of the subject of vibration monitoring as well as a lack of training, thus, lack of knowledge.

Learn More

Vibration and temperature readings provide vital data about the health of your machines. Uncover these insights with the SKF Pulse. Combining an easy-to-use sensor with a free mobile app, you can quickly and easily identify machine condition without the need for training or diagnostic expertise How to get started

Learn More

Portable Instruments for Condition Monitoring. 2. Continuous Monitoring Systems. 3. Software. 4. Shock Pulse Transducers, Adapters and Tools. 5. Vibration

Learn More

The shock pulse method was invented in the late 1960s. In rolling element bearings, there is a phenomenon where electric waves, or elastic waves

Learn More

Shock pulse method (SPM) is a technique for using signals from rotating rolling bearings as the basis for efficient condition monitoring of machines. From the innovation of the method in 1969 it has been further developed and broadened and is a worldwide accepted philosophy for condition monitoring of rolling bearings and machine maintenance. [1]

Learn More

The Shock Pulse Method is the monitoring and analyzation analysis that moni broad vibration band and then tries to isolate unique frequencies; SPM.

Learn More

Bearing check and control are efficiently performed by the shock pulse method. The portable device BALTECH VP-3450 is designed to control a vibration level

Learn More

The shock pulse method (SPM) has been widely used as a quantitative method for bearing condition monitoring. However, the shock value

Learn More

Vibration analysis and the Shock Pulse Method (SPM) are two of the most popular condition monitoring techniques used in Condition-Based Maintenance (CBM)

Learn More

Benefits of Vibration Analysis and Shock Analysis: Determine structural or rotating looseness or the presence of resonance Check bearing concentricity Detect misalignment or imbalance Establish your Repair Priorities based on the results Improve Your Preventive Maintenance Quality and Results Test Under Load without any planned shutdown

Learn More

Shock Pulse Monitoring A Snapshot. Unless an individual is involved with some form of machinery vibration analysis, the term "Shock Pulse" (Monitoring) is unknown and somewhat foreign. Officially, and accurately, it is a technology relying on the physical principle that sound travels undiminished through metal objects for great distances.

Learn More

Unless an individual is involved with some form of machinery vibration analysis, the term "Shock Pulse" (Monitoring) is unknown and somewhat foreign.

Learn More

Shock pulse monitoring SPM is an abbreviation for the Shock Pulse Method, which is a patented technique for using signals from rolling element bearings as the basis for efficient condition monitoring of machines. Instant evaluation of bearing condition is given in an easily understood green-yellow-red color scheme.

Learn More

Get the most complete picture of your valuable package's journey with an enDAQ shock and vibration recorder. enDAQ's vibration sensors and loggers offer a configurable, accurate and reliable solution for gathering data with accelerometers. These devices include two embedded accelerometers to provide a wide dynamic range to capture low amplitude

Learn More

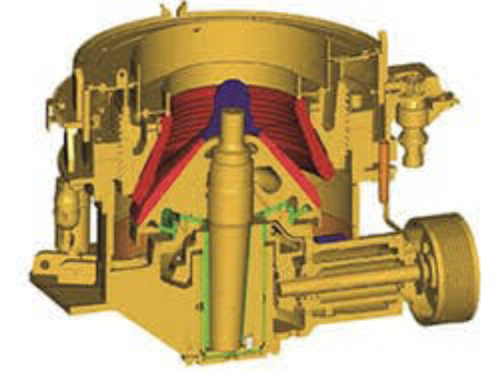

fritsch ball mill step plate quotation shock pulse meter calibration cone crusher mantle weight raymond mills spare eccentric bushing usa stone crusher machine cone crusher design. crusher thrust plate company in europe shock pulse method pdf impact crusher spare parts insert price list cone crusher parts name.

Learn More

Shock pulse monitoring Shock pulse monitoring SPM is an abbreviation for the Shock Pulse Method, which is a patented technique for using signals from rolling element bearings as the basis for efficient condition monitoring of machines. Instant evaluation of bearing condition is given in an easily understood green-yellow-red color scheme.

Learn More

If the philosophy of front line Condition Monitoring is utilized, shock pulse measurements would be utilized as the first stage of identifying anomalies.

Learn More

SPM will detect bearing problems while vibration will identify multiple faults (imbalance, misalignment, looseness, pump vane pass)in addition

Learn More

The results of this thesis show a distrust towards vibration monitoring, while other means of condition monitoring such as lube oil and thermal analysis is common on board. This distrust can be related to the complexity of the subject of vibration monitoring as well as a lack of training, thus, lack of knowledge.

Learn More

The SPM HD Shock Pulse Monitoring is a further development of Shock Pulse Method (SPM); which can be used for easy, fast and reliable diagnosis of the

Learn More

The results of this thesis show a distrust towards vibration monitoring, while other means of condition monitoring such as lube oil and thermal analysis is common on board. This distrust can be related to the complexity of the subject of vibration monitoring as well as a lack of training, thus, lack of knowledge.

Learn More