-

Call Us:+86-21-63353309

[email protected]

Call Us:+86-21-63353309

[email protected]

Gear hob machines from MHD Werkzeugmaschinen are designed for high-speed machining of cylindrical gears in large quantities, often in the workpiece

Learn More

As ITW used to say, "Good blanks make good gears." Back your hob out of the way and turn 'er on. Feed the hob in by hand until it just touches

Learn More

Know the Difference Between Gear Shaping and Gear Hob . Just like any sheet metal is fabricated to form the right mold, shape, size, and so on, gear manufacturing has certain machining processes such as shaping, hob , and so on. Gears are required to be set in motion, rotate, and raise the speed of any machine, industrial equipment

Learn More

I've bought a small hob machine which cuts spur gears only. It's a Mikron 112. The machine is complete and working, just needs cleaning and lubricating and a VFD fitted for the motor, I have a full set of change gears and a decent number of cutting hobs.

Learn More

Gear hob is done by using a multipoint cutting tool called gear hob. It looks like a worm gear having a number of

Learn More

The new "GE25A," a gear hob machine, will become available with a newly Easy and simple operation software for setting the machining

Learn More

How is a traditional hob machine set up to cut a spur gear? All "traditional" gear hob machines have an Index Constant. This constant, along with the number of teeth to cut and the number of starts in the hob cutter determine the index gear ratio and the index change gears. Some typical Index Constants are: 36, 30, 24, 15, 12, 10, etc.

Learn More

Reduction in Machine Setting Time settings of the fixture on the hob machine. There by, Index Terms- Fixtures, Gear Hob , Hob fixtures.

Learn More

Oct 27, · Gear hob is a quick and versatile process that is fundamental for gear manufacturing. Gear hob machines utilize a rotating cutting tool, or hob, to generate a

Learn More

YKG3120CNC6 manufacture suppliers gear hob machine operation setting ; Max. hob shift axial. 190mm ; Center distance between hob and worktable. 30~260mm.

Learn More

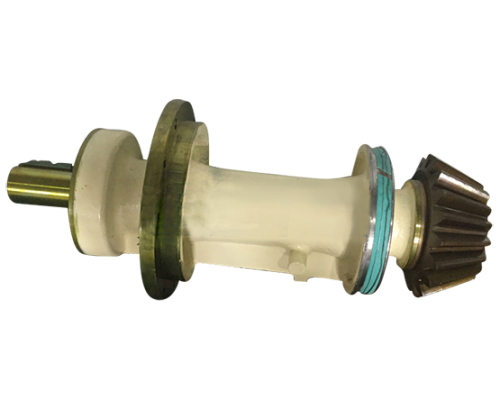

In hob spur gear the hob teeth are set parallel to the axis of rotation of the blank. For helical teeth bob , the axis of the hob is set over an angle to produce the proper helix. While worm gears are produced with the axis of the hob set the right angle to the gear blank. Generally two techniques are used in the hob process.

Learn More

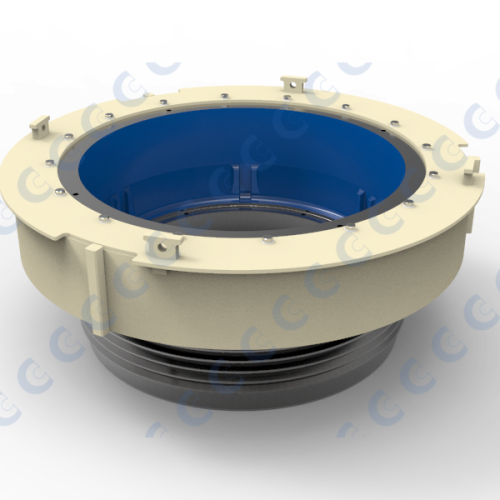

Gear Hobber Casting Set. $495.00. Add to Cart. The gear hobber is a machine for producing gears by the hob process: a rotating gear blank is fed into a gear hob (in the shape of a worm). The maximum capacity is about 4” in diameter, 20 dp (diametrical pitch), 1.25 module down to 1/10” diameter, 120 dp, 0.2 module.

Learn More

The hob machine is characterized in that a separate mechanism for hob shifting is not required. The hob shifting, as well as other machine

Learn More

China TIPTOP product range includes: Gear Hob Machine, Lathe, Vertical Machining Center, Milling Machine, Drilling Machine and Grinding Machine. I bought one set of gear hob machine from TIPTOP. There is no difference between their machine and European machine. I am very happy to save so much money. Their sales are nice.

Learn More

To change the longitudinal crowning from asymmetric to symmetric, a method of modified worm gear hob is proposed. The modification uses a modified machine tool setting and a modified hob

Learn More

During manufacturing of gears on Hob machine, the time taken for the setting of the hob fixture was very high. Whenever a gear of a new Root Diameter is to be manufactured, old fixture has to be removed & the relevant new fixture has to be installed. For changing of the fixture on the gear hob machine the time required was found out

Learn More

ease adjustment ofthe machine. 3.3 CNC GEAR HOBBING. The early 1970's was an important era in numerical control of machine tools, as.

Learn More

twothreads, the gear must advancetwotooth spaces for each revolution of that hob. This will double the speed of the work and double theproduction.another factors being equal (Fig. 22). With four threads in the hob, four teeth on the part will index with every revolu- lion of the cutter.

Learn More

Gear-hob machines use a rotating, multiple-tooth cutting tool called a hob for generating teeth on spur gears, worm gears, helical gears, splines,

Learn More

for the other gears ' manufacturing and reduce the no of settings of the fixture on the hob machine. There by, reducing company's cost & time.

Learn More

Course Description. Learn and understand fundamentals of gear manufacturing. Acquire knowledge and understanding of gear nomenclature, hob and shaping of spur and helical gears, and splines. Learn and understand hobber and shaper machine set-up, as well as gear tooth element inspection. Understand the manufacturing process before gear tooth

Learn More